Precision meets impact

The AXENT large-area spreaders are the perfect combination of impact, low ground pressure, and maximum spreading precision. The AXENT 90.1 is technically simple but equipped with a PTO shaft drive. It offers all RAUCH advantages in one unit: EMC dosing automation, GPS control, VariSpread, and OptiPoint thanks to the attached AXIS-M spreading technology. With the same container size, the AXENT 100.1 further enhances these capabilities with onboard hydraulics, interchangeable spreading units, a steering axle, and hydraulic AXIS spreading technology.

Model variants AXENT 90.1

| AXENT 90.1 With AXIS Powerpack V8 | Large area spreader with mineral fertiliser spreading unit, EMC mass flow control, SpeedServo setting cylinder, 8-fold part-width section control |

|---|---|

| AXENT 90.1 With Powerpack VariSpread pro | Large area spreader with mineral fertiliser spreading unit, EMC mass flow control, SpeedServo setting cylinder, part-width section control in 1 m steps |

Benefits

-

ISOBUS

Synergien nutzen - Effizienz steigern

Innovative RAUCH ISOBUS technology for the ISOBUS fertiliser spreader allows you to use your existing and familiar ISOBUS control panels from a wide range of suppliers and machines.

-

VariSpread pro

AXIS H 30.2/50.2 EMC (+W) and AXIS M 30.2/50.2 EMC (+W) with VariSpread pro feature electric feed point adjustment, adjusting the working width and application rate in a gliding process during spreading travel.

.Thanks to RAUCH SpeedServo actuators, the application rate and working width are continuously and steplessly adjusted to field wedges, sloping headland areas or non-opening tramlines in one-meter increments, even at high working speeds.

Also new is GapSpreading, which allows simultaneous shutdown from the outside and inside.

-

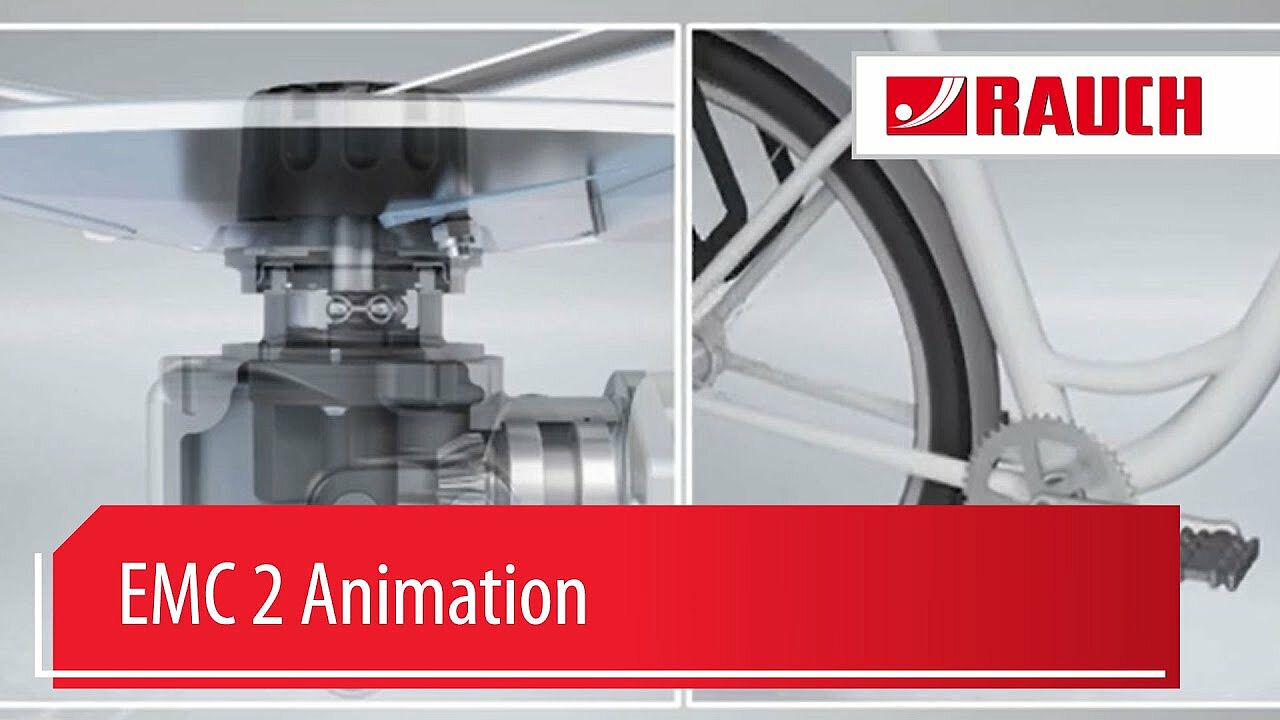

EMC®-2

The intelligent online automatic dosing system with e-bike technology

AXIS EMC® measures and controls the current application rate fully automatically on the left and right dosing gate separately. State-of-the-art magnetostriction torque sensors measure the drive torques of the two throwing discs without contact and with high precision, thereby permanently controlling the exact metering gate position for each side separately. EMC® uses magnetostrictive e-bike technology, proven millions of times over, from renowned system partner Schaeffler FAG.

High precision, elegant ease of use

.For the driver, this means simply entering the application rate and working width and start spreading. The spread rate adjusts in seconds, depending on the instantaneous fertilizer trickle characteristics and travel speed.

EMC® Advantage

.EMC® meters the left and right sides separately, unlike spreaders controlled by load cells. This allows for more metering precision and side-by-side distribution.

.EMC® detects and compensates for quality-related fertilizer flow rate fluctuations much faster than conventional weigh cell spreaders.

EMC® meters accurately and reliably even under extreme vibration conditions.

EMC® meters with high precision even on slopes.

EMC® measures the applied quantities in kg with high precision like a scale for your documentation.

Intelligent EMC® metering gate control automatically detects one-sided blockages and clogs.

EMC® precisely measures and controls left and right differential application rates when spreading with VariSpread in wedge areas.

EMC® precisely measures and controls the different spread rates on the right and left when spreading with partial area accuracy from application maps or with N-sensors.

-

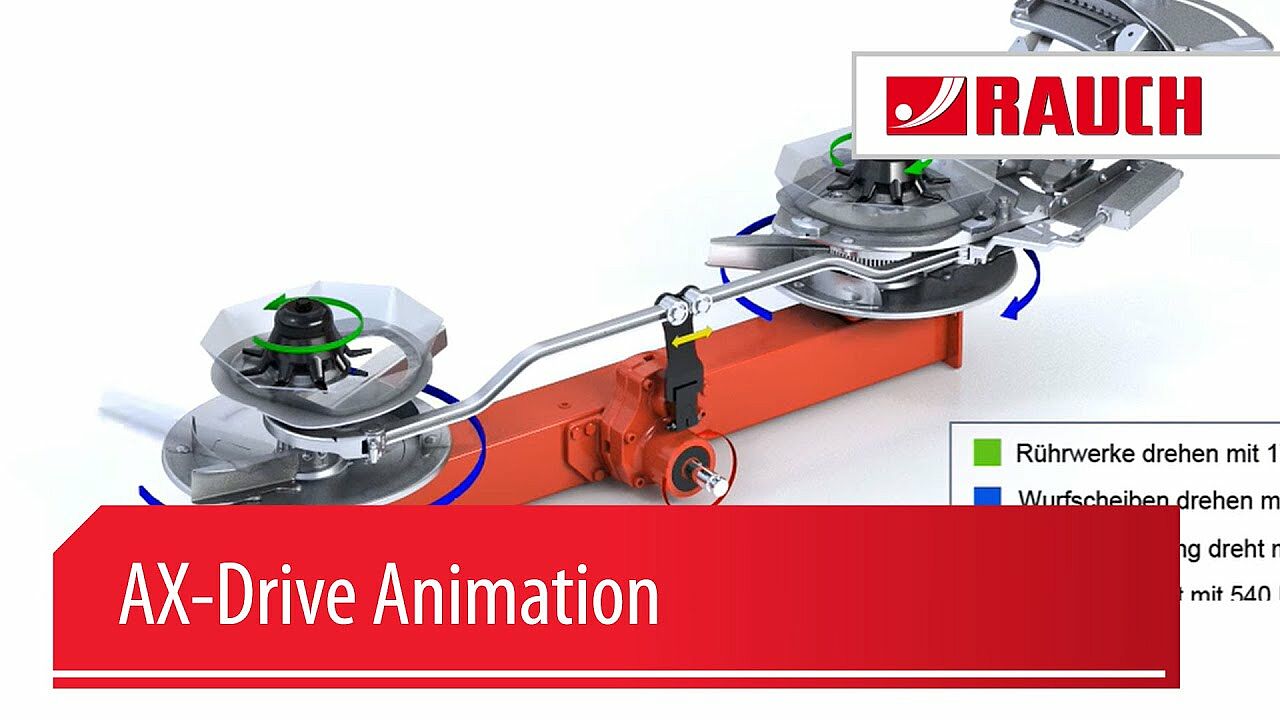

M-Drive

M-Drive: maintenance-free gearbox technology with overload protection

The innovative M-Drive for the throwing discs and the slow-running, fertilizer-friendly agitators is maintenance-free for years. All shafts and angular gears run in an oil or grease bath and are protected from fertilizer dust, dirt, moisture and mechanical damage by a robust frame construction.

.Unique in fertilizer technology, AXIS features overload protection systems that protect the entire gear unit, including the fertilizer-protecting agitators, from overload caused by jams, operator error or hard-shifting PTOs.

M-Drive performance data

.- Transmission input: PTO speed of 540 rpm

- Turntable speed: 900 rpm

- Agitator speed: 17 rpm pulsating and extremely gentle on fertilizer

AXIS M 50.2 EMC+W

- Gearbox input: PTO speed of 750 rpm

- Throwing disc speed: 900 rpm

- Stirrer speed: 17 rpm pulsating and extremely gentle on fertilizer

.

Intelligent agitator technology

.The innovative agitator drive for the slow-running, fertilizer-sparing agitators is

.

maintenance-free for years. Overload protection systems protect the entire agitator unit from overstress due to blockages.- extremely fertilizer-sponed: vibration agitator rotates at only 17 rpm

-

W | Remaining quantity scales

Always an eye on the remaining quantity

The scale integrated in the spreader gives a reliable indication of the remaining fertiliser in the container.

Overloading can thus be planned at the ideal time.

The "W" remaining quantity scale is part of the standard equipment of:

- AXIS M 30.2 EMC®+W

- AXIS M 30.2 EMC®+W dynamik ISOBUS

- AXIS M 50.2 EMC®+W

For AXIS M 30.2 EMC®+W, the optional residual quantity sensor indicates the minimum filling level.

-

High-Speed-Servos

SpeedServos | AXIS fertiliser spreaders are becoming even more efficient

The big SpeedServo advantage:

The adjustment speeds of the SpeedServos are 2.5 times higher than the previous spindle motor models. This opens up a world of superior response speeds and new performance dimensions for the AXIS M EMC ISOBUS spreaders and AXIS H EMC spreaders for fully-automatic fertiliser dispensing with EMC, headland dodging with OptPoint, area-specific spreading with application maps, and with sectional width spreading with section control.

Despite consuming considerably less energy, SpeedServos achieve up to 3 times higher actuating forces than comparable spindle motors. Its superior energy efficiency makes it ideal to use in ISOBUS machines, since the ISOBUS standard limits electrical power consumption.

In addition, SpeedServos are much more efficient at protecting against dust and dirt, as there is no longer any delicate and telescopic lifting rod. The effective, long-term sealing against moisture and dust as well as the simple, robust SpeedServo construction give extra long service life to the valuable electronic components.

Tools

Accessories

Hopper cover | AXENT

The hopper cover reliably protects the spreading material and can be effortlessly opened.

ISOBUS Terminal CCI 1200

Limited border spreading GSE AXIS/AXENT

The GSE 30 and GSE 60 enable sharp-edged border spreading on the left and right side directly on the field boundary with half-side spreading. The distance to the border can be varied between 0 to 3 m. GSE 30 is the thrower shield for AXIS 20.2 / 30.2. GSE 60 is suitable for use with AXIS 50.2 and AXENT.

Optionally, GSE 30/60 can be remotely controlled hydraulically using the FHD 30-60 remote control via a double acting tractor control valve.

Another option is the GSE sensor. This shows the current status of the GSE in the operating screen of the software.

Limited border spreading Telimat AXIS

TELIMAT T25/T50

TELIMAT enables precise, hydraulically remote-controlled edge and border spreading right from the first tracks. The double-adjustable spreading compartments redirect the fertiliser to fulfil the requirements of the European environmental standard.

Without the need for stopping and dismounting, the Telimat T25 swings up and down on the AXIS 20 and 30 via a single-acting tractor control valve. AXIS M 50.2 W ISOBUS is equipped with a TELIMAT T50 remote control as standard.

-

Ejection discs

Everything revolves around precision.

Ejection discs Working width Beschreibung S12 Working width: 42-50 m S4 Working width: 18-28 m S6 Working width: 24-36 m S8 Working width: 30-42 m * Coated spreader vanes with VXR plus

Technical data and equipment

| Model variant | AXENT 90.1 With AXIS Powerpack V8 | AXENT 90.1 With Powerpack VariSpread pro |

| Basic machine | ||

| Working width [ m ] | 18 – 50 | 18 – 50 |

| Hopper volume [ l ] | 9,400 | 9,400 |

| Max. capacity [ kg ] | 8,400 | 8,400 |

| Container size [ cm ] | 255 x 770 | 255 x 770 |

| Filling height [ cm ] | 300 | 300 |

| Filling width [ cm ] | 255 | 255 |

| Empty weight [ kg ] | 4,600 | 4,600 |

| Track width [ cm ] | 200 x 225 | 200 x 225 |

| Tractor attachment | Drawn | Drawn |

| Axle type | Rigid axle | Rigid axle |

| Hitching | Bottom hitching | Bottom hitching |

| Axle load [ t ] | 10 | 10 |

| Brake | Pneumatic brake | Pneumatic brake |

| Drive | M drive: Universal drive shaft with ratchet safety clutch 540 rpm | M drive: Universal drive shaft with ratchet safety clutch 540 rpm |

| Metering | ||

| Slide actuation/quantity regulation | EMC mass flow control | EMC mass flow control |

| Servomotors | Slide actuation elec. HighSpeed servos | Slide actuation elec. HighSpeed servos |

| W remaining quantity scales | Yes | Yes |

| Variable Rate Control | Yes | Yes |

| Electronics | ISOBUS electronics with job computer | ISOBUS electronics with job computer |

| Section control | VariSpread V8 partial width controller | VariSpread pro partial width controller |

| Limited border spreading | Limited border spreading with TELIMAT, Limited border spreading with GSE | Limited border spreading with TELIMAT, Limited border spreading with GSE |

![[Translate to English:] [Translate to English:]](/fileadmin/duengerstreuer/axent-90/axent-90-1-rauch-grossflaechenstreuer-3827-h.jpg)

![[Translate to English:] Limited border spreading GSE AXIS/AXENT](/fileadmin/_processed_/0/5/csm_gse-30-60-rauch-duengerstreuer-scheibenstreuer-1427-w_bdb338d96c.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/5/csm_gse-30-60-rauch-duengerstreuer-scheibenstreuer-1427-w_64a3828b3c.jpg)