The narrow one

Equipped with innovative detailed solutions, it is ideal for professional use in fruit, wine and hop cultivation.

Angled container corners, slide adjustment at the front of the container and a small outside width enable precise fertilisation that is gentle on plants, even in crops with narrow row spacing.

Model variants MDS 8.2

| MDS 8.2 K | with flow rate regulation |

|---|---|

| MDS 8.2 D | without flow rate regulation |

| MDS 8.2 R | folgt |

| MDS 8.2 C | Electrical single slide actuator system with E-Click |

| MDS 8.2 Q | Speed-dependent, electronic fertiliser metering, QUANTRON-A |

| MDS 8.2 W | Speed and weight-dependent fertilizer metering, weighing frame, QUANTRON A |

![[Translate to English:] [Translate to English:]](/fileadmin/duengerstreuer/mds-8-2-duengerstreuer-scheibenstreuer-19-12.png)

Benefits

-

Multi-Disc-System

Ingenious solutions for more spreading precision

The tried and tested multi-disc system, which gives the MDS fertiliser spreader its name, is all about the spreader discs. The simple adjustment of the spreader vanes in length and angle enables the fertiliser spreader to be perfectly adapted to different materials and spreading widths. It's precise and reliable when it comes to normal fertilisation, late fertilisation and yield-optimised spreading near field boundaries (right and left side).

This means: highly precise fertiliser distribution and the achievement of exact spreading patterns for all types of fertiliser, fine seeds and slug pellets.

Thanks to the clearly visible, three-dimensional position display, the spreader vanes can be easily adjusted in length and angle even after long use.

-

Single-chamber principle

MDS demonstrates its strengths in everyday use

The MDS single-chamber container system is ideal for use in clipped or small-sized terrain:

There's no one-sided emptying of the container, even with one-sided closed dispensing gate. The spreading material can be used right down to the last grain. This saves time and increases efficiency.

-

Transmission and agitator technology

Robust, highly durable and maintenance-free

The heart of the MDS spreader is the maintenance-free oil bath gearbox. All shafts have double bearings. The agitator shaft is made of high-quality stainless steel. Even after many years of hard use, no oil change is required.

Crucial factors for the quality of the spread pattern:

A slowly rotating agitator finger (180 rpm) ensures that the fertiliser is dispensed hassle-free, gently and constantly.

The special shape of the dispensing gate allows precise dispensing of the smallest (3 kg/ha) and also larger amounts of fertiliser and is thus also suitable for spreading slug pellets, fine seeds and rice.

The granulate is gently transferred to the spreader vane via the dispensing duct with brushes. Thanks to the special notches on the spreader vanes, even the most pressure-sensitive types of fertiliser retain their spreading properties.

The high disc speed of 980 rpm accelerates the fertiliser to be spread to an ideal discharge speed. The high ejection energy ensures a safe flight and is crucial for achieving exact fertiliser distribution.

MDS spreaders are equipped with corrosion-free agitators.

Since October 2014, RAUCH has been equipping the complete MDS series with new, corrosion-free agitator heads. The new MDS agitator head is made of high-quality, composite plastics. Both in terms of abrasion resistance and corrosion resistance, the plastic agitator sets new standards compared to the detached cast iron version. Rust stains and stubborn agitator heads corroded onto the agitator shaft are now a thing of the past. The well-known RAUCH agitator fingers are still made of high-quality tool steel.

-

Agitators | MDS

RWK 7K for grass seeds

With the RWF agitator finger, MDS can be quickly converted into a seed spreader with a wide spreading width.

Agitator RWK 15 for powdery fertilisers

With RWK 15, powdery fertilisers are also fed cleanly to the dispensing gates.

RWK 6K for caking fertiliser

-

Direct-Flow-Control

Precise and predictable dosing

The smooth and incremental pre-selection of the volume to be spread starting from 3 kg/ha is based on the large, volume-proportional direct flow control scale, in short 'DfC scale'. The DfC scale allows an exact change to be made to the application rate without any additional aids.

It's very easy:

A 10% higher scale value means a 10% higher application rate. This greatly simplifies the precise setting of the ideal application rate from one field to another.

-

Gate version

The right gate version for every tractor

The dispensing gates are remotely and elegantly opened and closed mechanically, hydraulically, or electrically on the left and right side independent of each other. Spreading is even possible on wedge-shaped surfaces with partial width accuracy.

-

E-Click

With E-Click, RAUCH offers a convenient electrical operating system

The special thing about E-Click: The electrical dispensing gates can be controlled separately from each other on the left and right side using a toggle switch. A control diode displays the current gate position. This greatly minimises operating errors.

The E-Click control terminal is elegantly connected to the fertiliser spreader by a cable. The need to connect hydraulic hoses is thus completely eliminated. High-quality, dust and splash-proof actuators ensure a high level of operating comfort and a long service life for your investment.

The electric E-Click dispensing gate control is particularly suitable for smaller tractors with only a few hydraulic connections.

-

QUANTRON-A | MDS

Electronic dosing system to perfection

QUANTRON-A regulates the opening position of the dispensing gates and thus the flow rate depending on the driving speed and the specified application rate.

When the driving speed varies, the preselected application rate always stays the same. QUANTRON-A impresses users with its large, clear display, intuitive menu navigation, and USB port.

All functions can be electrically remotely controlled, conveniently and safely with just one hand: MDS with QUANTRON-A not only offers elegant ease of use but also increases the precision and efficiency when spreading valuable fertiliser granules.

Tools

Accessories

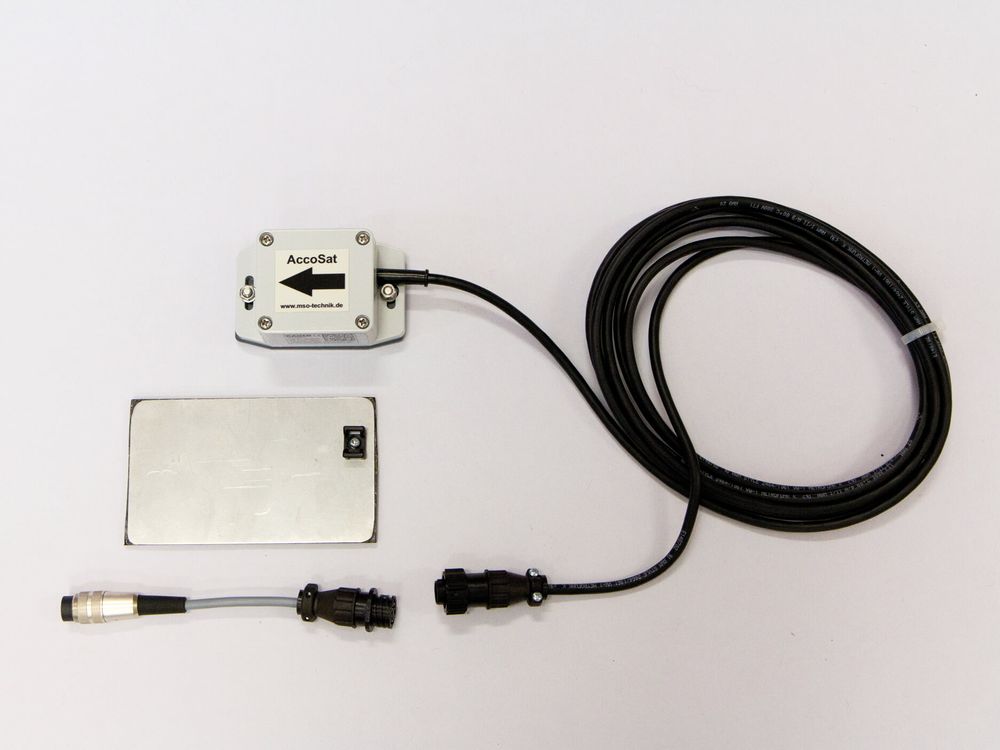

GPS speed sensor

In order to be able to regulate spreading according to the driving speed, the QUANTRON-A and QUANTRON-K2 scatter computers, and the ISOBUS display all require a speed signal. This usually comes via the 7-pin signal socket or the ISOBUS from the tractor unit. If the tractor itself is not equipped with this signal, either a wheel sensor must be retrofitted or you can use this GPS speed sensor.

A GPS signal in combination with an acceleration sensor generates a high-precision speed signal. This is especially recommended if the spreader is used in combination with several tractors or is also shared by different companies.

Another great advantage of this is that the slip of the tractor tyres in wet conditions or slopes does not matter and does not adversely affect the spreading result.

Limited border spreading GSE MDS

If the tracks lie directly on the edge of the field, the thrower shield GSE 7 can be used in combination with one-sided spreading. The distance to the

border can be varied between 0 to 2 m. With a hydraulic remote control, GSE 7 can be raised and lowered from the cab via a single-acting tractor control valve (optional).

The precise MDS edge spreading and border thrower shields comply with the European environmental standard (EN 13739-1) for fertiliser spreaders and make a decisive contribution to greater economy and environmental protection.

GPS control with CCI 800

In order to use the QUANTRON-A to automatically switch part-width sections and headlands via GPS or to scatter application maps, the QUANTRON-A is connected to the CCI.800 terminal via a serial interface.

In this case, the CCI.800 is not used as an ISOBUS terminal, but as a GPS terminal that, in combination with a GPS receiver, switches part-width sections via SectionControl or processes application maps via the TaskController.

Practical test set

More safety when spreading

RAUCH PPS 5 Practical test set permits cross-distribution to be checked and corrected quickly and easily in the field. This provides even more reliability and accuracy during spreading, particularly with fertilisers of lower quality, problematic discharge properties or unknown origin.

In combination with the clear and comprehensible AXIS-CDA tuning logic, corrections are amazingly easy and secure.

PPS 5 components:

- 10 collecting trays

- 5 measuring cylinders

- 1 roller tape measure

- clear, logical operating instructions.

Row spreading device RV 2M

MDS with RV 2M - for accurate metering

The RV 2M row spreading device enables selective nutrient application in the root area of row crops. No granulate falls into the machine track. This saves valuable fertiliser. The RV 2M can be easily and variably adjusted to row distances between 2 and 5 m, and can be converted back from row to area spreading in only a few minutes.

RV 2M can be combined with all MDS models.

Technical data and equipment

| Model variant | MDS 8.2 K | MDS 8.2 D | MDS 8.2 R | MDS 8.2 C | MDS 8.2 Q | MDS 8.2 W |

| Basic machine | ||||||

| Working width [ m ] | 10 – 24 | 10 – 24 | 10 – 24 | 10 – 24 | 10 – 24 | 10 – 24 |

| Hopper volume [ l ] | 500 | 500 | 500 | 500 | 500 | 500 |

| Max. capacity [ kg ] | 800 | 800 | 800 | 800 | 800 | 800 |

| Container size [ cm ] | 108 x 108 | 108 x 108 | 108 x 108 | 108 x 108 | 108 x 108 | 108 x 108 |

| Filling height [ cm ] | 92 | 92 | 92 | 92 | 92 | 92 |

| Filling width [ cm ] | 98 | 98 | 98 | 98 | 98 | 98 |

| Empty weight [ kg ] | 190 | 190 | 190 | 190 | 190 | 249 |

| Tractor attachment | Three-point category I/II | Three-point category I/II | Three-point category I/II | Three-point category I/II | Three-point category I/II | Three-point category I/II |

| Drive | M drive: Universal drive shaft with shear bolt 540 rpm | M drive: Universal drive shaft with shear bolt 540 rpm | M drive: Universal drive shaft with shear bolt 540 rpm | M drive: Universal drive shaft with shear bolt 540 rpm | M drive: Universal drive shaft with shear bolt 540 rpm | M drive: Universal drive shaft with shear bolt 540 rpm |

| Metering | ||||||

| Slide actuation/quantity regulation | Hydraulic metering slide | Hydraulic metering slide | Hydraulic metering slide | Electrical metering slide | Mass flow control via scales | |

| Servomotors | - | - | - | Slide actuation elec. Linear actuator | Slide actuation elec. Linear actuator | Slide actuation elec. Linear actuator |

| W remaining quantity scales | No | No | No | No | No | Yes |

| Variable Rate Control | No | No | No | No | Yes | Yes |

| Electronics | - | - | - | EN- Bedienung E-Click | QUANTRON-A spreading system | QUANTRON-A spreading system |

| Section control | VariSpread V2 partial width controller | VariSpread V2 partial width controller | VariSpread V2 partial width controller | VariSpread V2 partial width controller | VariSpread V2 partial width controller | VariSpread V8 partial width controller |

| Limited border spreading | Limited border spreading with GSE | Limited border spreading with GSE | Limited border spreading with GSE | Limited border spreading with GSE | Limited border spreading with GSE | Limited border spreading with GSE |

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/c/csm_bild-folgt-Platzhalter-st-609-w_72d00fee9d.jpg)

![[Translate to English:] Limited border spreading GSE MDS](/fileadmin/_processed_/4/e/csm_gse-7-rauch-duengerstreuer-scheibenstreuer-5765_9f87f4d6aa.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/e/csm_gse-7-rauch-duengerstreuer-scheibenstreuer-5765_8d1653118e.jpg)

![[Translate to English:] Row spreading device RV 2M](/fileadmin/_processed_/1/7/csm_wirkungsweise-rauch-duengerstreuer-scheibenstreuer-RFZ-RR-w_adf532f7cb.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/7/csm_wirkungsweise-rauch-duengerstreuer-scheibenstreuer-RFZ-RR-w_1f562652dc.jpg)

![[Translate to English:] M 30](/fileadmin/_processed_/b/8/csm_mds-m30_4043b1f754.jpg)