AERO-GT 60.2

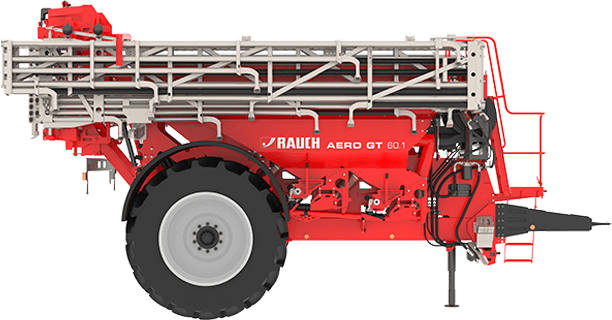

Trailed pneumatic fertilizer spreader

A new dimension in fertilizer technology:

Impact power paired with maximum precision even for fertilizers with problematic flight characteristics are the strengths of the trailed RAUCH pneumatic fertilizer spreader. AERO GT 60.1 is designed for large farms where maximum precision, outstanding economy and high impact power are paramount.

With AERO GT it is even possible to dose a different quantity at each part width section. This means that a different application rate can be applied in a small area every 6 meters. Partial area accurate fertilizing gets a new dimension.

Benefit from the AERO advantages:

- High-precision spreading even of poorly flying fertilizers, such as SSA or urea on large working widths.

- Marginal spreading means 100% fertilizer to the last row without losses on the way

- Large application windows - AERO spreads precisely even in windy conditions

- Efficient fertilizer spreading: precise lateral distribution, hardly any double-spread areas, ideal connection on the headland, no fertilizer in the tracks

Model variants AERO GT 60.1

| AERO GT 60.1 | 36 m | Pneumatic fertiliser spreader with 36 m operating width |

|---|---|

| AERO GT 60.1 | 32 m | Pneumatic fertiliser spreader with 32 m operating width |

| AERO GT 60.1 | 30 m | Pneumatic fertiliser spreader with 30 m operating width |

Benefits

-

MultiRate 6

The innovative technology of the new hydraulically driven MultiRate metering units allows a separate spread rate for each of the six boom sections. This allows application maps with an even more precise application rate.

-

M-Drive | AERO-GT

M-Drive: Wide-angle universal drive shaft with Vario pump 650-1000 rpm

-

ISOBUS

Synergien nutzen - Effizienz steigern

Innovative RAUCH ISOBUS technology for the ISOBUS fertiliser spreader allows you to use your existing and familiar ISOBUS control panels from a wide range of suppliers and machines.

-

Boom

The boom: Designed for stability, longevity and easy cleaning. The support tubes of the boom (made of stainless steel) are designed to serve as fertiliser conveyor pipes at the same time. The free-hanging boom package is attached via two independently suspended pendulums with articulated eyes, so safe and secure guidance of the boom in the field is guaranteed under all conditions.

High operating speeds are possible thanks to the intelligent adjustment of the pendulum frame suspension, the damping of the boom via nitrogen bubbles and the hydropneumatic chassis. The standard 6-way section control avoids fertiliser losses and over-fertilisation on wedge-shaped inclines and at field boundaries.

A powerful hydraulic system finishes the folding process in just 90 seconds. Boom approach protection provides security when things get tight.

Tools

Accessories

Hopper cover | AERO GT

The hopper cover reliably protects the spreading material and can be effortlessly opened.

Rear view camera

The RAUCH rear-view camera for RAUCH ISOBUS fertiliser spreaders also provides a good view to the rear, even on tall machines. This increases work safety when manoeuvring and also when spreading. The robust camera body is attached to the rear of the spreader. A protective plate prevents radiation and reduces the dirtying of the optics. The direction of the camera can be adjusted depending on the application.

The rear-view camera is compatible with the RAUCH ISOBUS universal terminals. Moreover, the camera can be connected to all terminals that have an AEF-compliant video input.

The rear-view camera is available for use with AXIS-ISOBUS, AXENT and AGT.

ISOBUS Terminal CCI 1200

Distance Control

Many farmers value the automatic linkage guidance that distance control provides. Ultrasonic sensors ensure that the linkage is always at the optimum height and appropriately angled to the crop. The driver has less to worry about and can concentrate more fully on adjusting and monitoring the AERO GT 60.1.

FreeLane

With the new RAUCH FreeLane system for the AERO GT pneumatic fertiliser spreader, for the very first time it is possible to avoid spreading fertiliser into tyre tracks. For tracks up to 36 m, FreeLane guarantees that of over 4% of valuable fertiliser will be saved with every use. The big advantage: Thanks to the strict separation of the spreading areas in the track area, the needs-based nutrient supply to the neighbouring plants is maintained.

Nowadays, the maximum tyre widths of tractors and trailed agricultural machines is 75 cm in order to reduce ground load. It is very unfavourable and often even detrimental if mineral-based fertiliser is applied in lanes up to 2 x 75 cm wide. In tyre tracks, there are no plants growing that can extract and absorb the fertiliser from the soil. Until now, the precious fertiliser that lands in the tracks could not be used.

The two easily-adjustable vanes on the AERO GT nozzles on the left and right of each track make it impossible for fertiliser to land in the tracks. The spread rate is precisely controlled by means of special tyre track cam wheels in the corresponding sections. The FreeLane system is flexible and can be easily and quickly adapted to different track and tyre widths.

FreeLane offers significant savings potential in terms of fertiliser and costs. At a spreading width of 24 m, that's a fertiliser savings of 6.25% (!), and at 36 m of 4.2% (!) per hectare, without negatively impacting the nutrition of the plants. This substantial reduction also contributes significantly to optimising the fertiliser balance in accordance with the new Federal Fertiliser Ordinance.

If, as is customary in controlled traffic (CTF), the tracks are in the same places as in previous years, the quantity of fertiliser in these tracks will accumulate in large quantities over the years due to the lack of absorption by plants.

The new RAUCH FreeLane system, with its special guides and changes to the cam wheel metering system, ensures that no fertiliser gets scattered into the tracks. And plants will continue to be uniformly fertilised.

Fine metering shafts

With the fine metering shafts (option), very small quantities of slug pellets or fine seeds can be precisely distributed.

Technical data and equipment

| Model variant | AERO GT 60.1 | 36 m | AERO GT 60.1 | 32 m | AERO GT 60.1 | 30 m |

| Basic machine | |||

| Working width [ m ] | 30 – 36 | 30 – 36 | 30 – 36 |

| Hopper volume [ l ] | 6,300 | 6,300 | 6,300 |

| Max. capacity [ kg ] | 5,000 | 5,000 | 5,000 |

| Container size [ cm ] | 380 x 160 | 380 x 160 | 380 x 160 |

| Filling height [ cm ] | 315 | 315 | 315 |

| Filling width [ cm ] | 380 | 380 | 380 |

| Empty weight [ kg ] | 7,000 | 7,000 | 7,000 |

| Track width [ cm ] | 225 x 270 | 225 x 270 | 225 x 270 |

| Tractor attachment | Drawn | Drawn | Drawn |

| Axle type | Rigid axle | Rigid axle | Rigid axle |

| Hitching | Top hitching | Top hitching | Top hitching |

| Axle load [ t ] | 10 | 10 | 10 |

| Brake | Pneumatic brake | Pneumatic brake | Pneumatic brake |

| Drive | M drive: Wide-angle universal drive shaft with Vario pump 650-1,000 rpm | M drive: Wide-angle universal drive shaft with Vario pump 650-1,000 rpm | M drive: Wide-angle universal drive shaft with Vario pump 650-1,000 rpm |

| Metering | |||

| Slide actuation/quantity regulation | Quantity regulation via metering rollers | Quantity regulation via metering rollers | Quantity regulation via metering rollers |

| Variable Rate Control | Yes | Yes | Yes |

| Electronics | ISOBUS electronics with job computer | ISOBUS electronics with job computer | ISOBUS electronics with job computer |

| Section control | 6-fold partial width controller | 6-fold partial width controller | 6-fold partial width controller |

| Limited border spreading | Limited border spreading with fixed working width | Limited border spreading with fixed working width | Limited border spreading with fixed working width |

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/2/d/csm_RAUCH_Duengerstreuer_MultiRate6_w_ae616e69dc.jpg)

![[Translate to English:] Distance Control](/fileadmin/_processed_/0/b/csm_distance-control-rauch-duengerstreuer-pneumatikstreuer-9373-w_aef721ef87.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/b/csm_distance-control-rauch-duengerstreuer-pneumatikstreuer-9373-w_d51aad852d.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/2/csm_distance-control-rauch-duengerstreuer-pneumatikstreuer-9225-w_c1c887ab57.jpg)

![[Translate to English:] FreeLane](/fileadmin/_processed_/a/a/csm_freelaine-rauch-duengerstreuer-pneumatikstreuer-04-w_1241dea269.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/a/csm_freelaine-rauch-duengerstreuer-pneumatikstreuer-04-w_433a791073.jpg)

![[Translate to English:] Compressed air](/fileadmin/_processed_/5/9/csm_druckluft-rauch-duengerstreuer-pneumatikstreuer-4170-w_528ed7de6e.jpg)

![[Translate to English:] Fine metering shafts](/fileadmin/_processed_/d/5/csm_feindosierwalze-rauch-duengerstreuer-pneumatikstreuer-87-w_2944e224d5.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/d/5/csm_feindosierwalze-rauch-duengerstreuer-pneumatikstreuer-87-w_97aa87fbad.jpg)