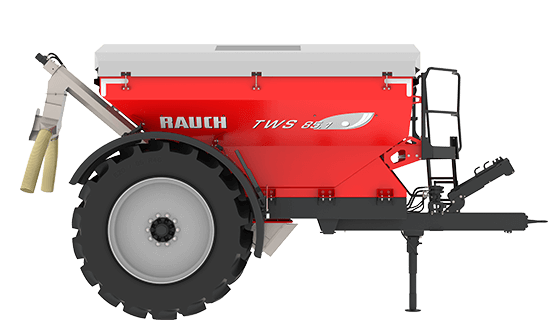

Precision large-area fertiliser spreader

Precise fertiliser technology for high output with maximum flexibility

The TWS 85.1 ideally fulfils practical requirements for high output, low ground pressure and maximum spreading precision.

The concept is based on the combination of a standard 3-point mounted fertiliser spreader with a high-volume transport wagon. The suspended design distributes the weight over three axles to protect the soil.

The convenient QUANTRON-A TWS control unit with fully automatic fertiliser transfer function increases the efficiency of professional fertilisation.

Model variants TWS 85.1

| TWS 85.1 M | PTO shaft, without fertiliser spreader, rigid drawbar, hydraulic auger shutter slide, PTO shaft drive through |

|---|---|

| TWS 85.1 H | Hydraulic, without fertiliser spreader, rigid drawbar, hydraulic auger shutter slide, hydraulic connections |

| TWS 85.1 HT | TWS with AXIS HT 50.2 EMC ISOBUS |

Benefits

-

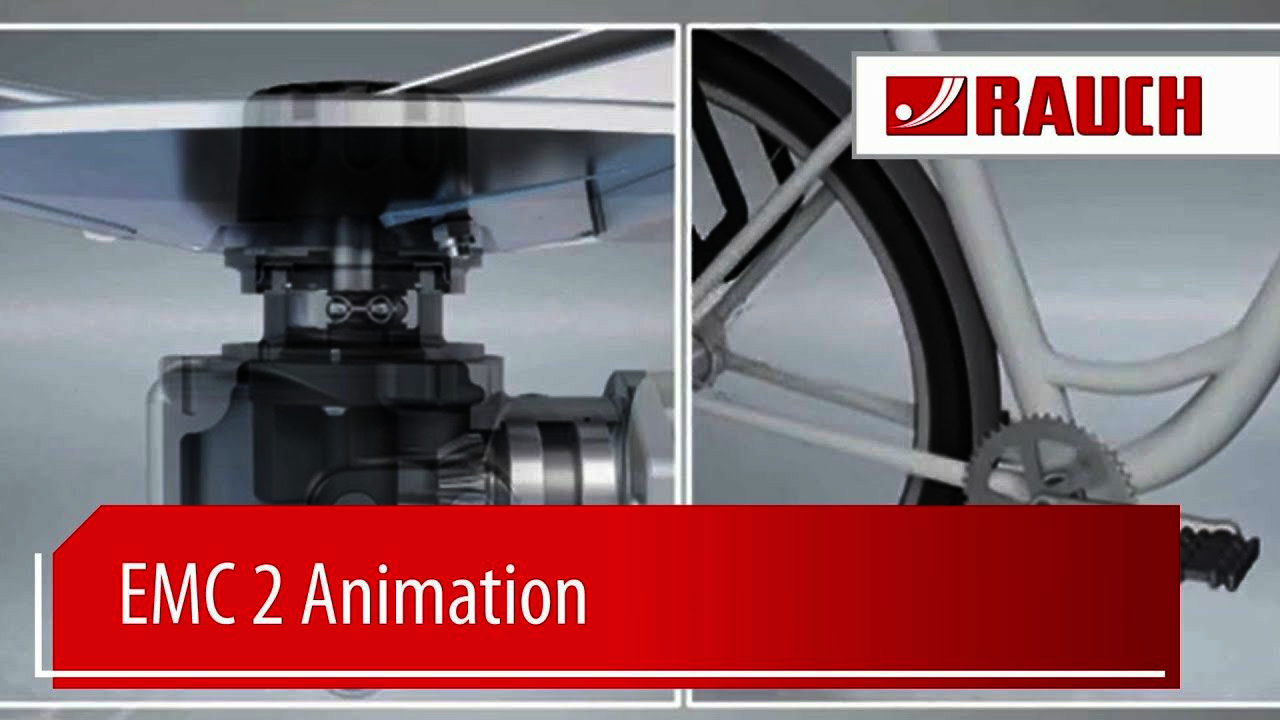

EMC®-2

The intelligent online automatic dosing system with e-bike technology

AXIS EMC® measures and controls the current application rate fully automatically on the left and right metering slides separately. State-of-the-art magnetostriction torque sensors measure the drive torques of the two spreading discs without contact and with high precision, thereby permanently regulating the exact metering slide position for each side separately. EMC® uses the magnetostriction e-bike technology from renowned system partner Schaeffler FAG, which has proven itself millions of times over.

High precision, elegant ease of use

For the driver, this means simply entering the spread rate and working width and starting to spread. The spread rate is adjusted in seconds depending on the current fertiliser trickle properties and the driving speed.

EMC® advantage

In contrast to spreaders with control via load cells, EMC® doses the left and right sides separately. This enables greater metering precision and accurate lateral distribution.

EMC® recognises and compensates for quality-related fertiliser flow rate fluctuations much faster than conventional weighing spreaders with weighing cells.

EMC® doses precisely and reliably even under extreme vibrations.

EMC® doses with high precision even on slopes.

EMC® measures the applied quantities in kg with the same high precision as a scale for your documentation.

The intelligent EMC® metering slide control automatically recognises one-sided blockages and obstructions.

EMC® precisely measures and controls the different application rates on the right and left when spreading with VariSpread in wedge-shaped areas.

EMC® measures and controls the different spread rates on the right and left when fertilising with partial area precision from application maps or with N-sensors.

-

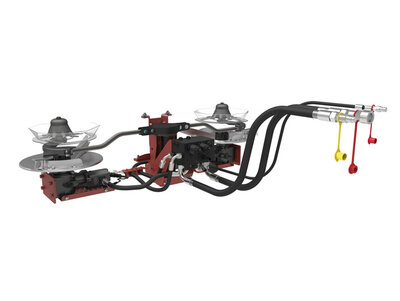

CDA spreading technology | remote-controlled

Precision meets ease of use

As a further option, the AXIS fertiliser spreaders can be equipped with an electric drop point adjustment. Setting a twin-disc fertiliser spreader has never been so easy. All setting parameters can be easily taken from the clearly laid out fertiliser chart and conveniently entered into the logically structured input screen on the control terminal. It is even easier to transfer the complete setting values from the fertiliser chart smartphone app to the spreader via a WLAN module, which even eliminates the need to enter the data manually. Simply select the fertiliser and the machine is set (optional accessory).The high-quality, dust and splash-proof, electric SpeedServo actuators with state-of-the-art sensor technology adjust the setting of the metering slides and the feed points of the coaxial CDA spreading technology fully automatically on the left and right side. At the same time, the specified spreading disc speed is automatically approached on the hydraulically driven AXIS-H spreaders.

This means that AXIS is precisely matched to the fertiliser type and quality, the spreading material properties, the desired application rate and working width. Manual adjustment steps are completely eliminated with AXIS H; with AXIS M, only the Telimat boundary spreading device needs to be adjusted. -

ISOBUS

Utilising synergies - increasing efficiency

Innovative RAUCH ISOBUS technology for the ISOBUS fertiliser spreaders enables familiar operation with existing ISOBUS operating terminals from a wide range of suppliers and machines.

-

H-Drive

Wartungsfreie, hydraulische Antriebstechnologie

RAUCH has been relying on hydraulic disc drives since the 1990s. The innovative H-Drive keeps the spreading disc speed constant - regardless of the tractor speed. This enables fuel-saving work without spreading errors.

The speed adjusts optimally during edge and border spreading, so no Telimat is required. Switching from edge to border spreading is done at the touch of a button, manual adjustments increase precision, especially on slopes.

-

VariSpread pro

AXIS H 30.2/50.2 EMC (+W) and AXIS M 30.2/50.2 EMC (+W) with VariSpread pro feature electric feed point adjustment and thus adjust the working width and spread rate during the spreading travel in a smooth process.

Thanks to the RAUCH SpeedServo servomotors, the spread rate and working width are continuously and steplessly adjusted to field wedges, sloping headlands or non-emerging tramlines in one metre steps, even at high working speeds.

Another new feature is GapSpreading, which allows you to switch off from the outside and inside at the same time.

Tools

Accessories

AXMAT duo

RAUCH AXMAT duo | Fully automatic, radar-based spreading pattern control

The new AXMAT duo has 54 radar sensors positioned in a stationary, semi-circular shape below the two fertiliser spreader discs.

AXMAT duo scans the area that was spread online using its innovative radar technology. After scanning, the intelligent software instantly recognises the location, character and expansion of the spread pattern. Within fractions of a second, a new setting for the AXIS spreading technology is calculated once spread pattern deviations have been detected and the spreading area is driven to remotely with the help of the extra-fast SpeedServo motors. Fully automatic, the spreading pattern is optimised every second by adjusting the fertiliser output point on the spreader discs on both sides separately.

AXMAT duo opens up new worlds of performance when it comes to professional fertiliser technology. Negative influences caused by the fertiliser properties or the ambient conditions are automatically detected and compensated for while spreading. AXMAT certainly impresses users with its wide range of usage options for fertiliser granules and slug pellets. The system is only limited if precise spreading is no longer technically possible due to fertiliser quality, weather conditions or the selected working width or spreader discs.

The dream of the self-adjusting fertiliser spreader is now a reality thanks to AXIS H 50.2 EMC®+W and AXMAT duo in conjunction with EMC automatic metering technology for the left and right dispensing gates.

AXMAT is only available for AXIS H 50.2 EMC®+W (NG job computer, from SN 09-050000 onwards).

AXIS lighting with warning signs

High-quality LED headlights, integrated in the warning signs, ensure more safety on the road.

SpreadLight | AXIS

Modern GPS-controlled OptiPoint headland management systems and VariSpread section controls make precise fertiliser spreading possible - even at night. So far, however, it has been very difficult for the driver to visually check the individual spreader functions while spreading in the dark. In addition, obstacles in the spreading area pose a risk at night.

Thanks to the SpreadLight work lights, RAUCH has solved these problems. Modern, powerful LED work lights directly above the two spreader discs of the fertiliser spreader illuminate the spread fans on the left and right side.

The driver has the spread fan in full view thanks to SpreadLight. Possible incorrect settings or clogging at the dispensing gates are recognised immediately. Moreover, the operator can respond more quickly to difficult-to-detect obstacles or danger spots in the outer spreading area in the dark, especially when it comes to wide spreading widths.</p<p>Unlike the tractor's work lights, SpreadLight is specifically aimed at the spreading fan. The fertiliser granules thereby reflect the intensive LED light.

As simple as it is convenient, SpreadLight is remotely controlled by the ISOBUS terminal via a touchscreen. The operator can choose whether the headlamps are permanently lit or automatically switch off and on in the headland in order to avoid blinding oncoming traffic on the road. SpreadLight can be retrofitted as an option for all mechanical and hydraulically driven RAUCH AXIS.2 ISOBUS fertiliser spreaders.

Limited border spreading GSE AXIS/AXENT

The GSE 30 and GSE 60 enable sharp-edged border spreading on the left and right side directly on the field boundary with half-side spreading. The distance to the border can be varied between 0 to 3 m. GSE 30 is the thrower shield for AXIS 20.2 / 30.2. GSE 60 is suitable for use with AXIS 50.2 and AXENT.

Optionally, GSE 30/60 can be remotely controlled hydraulically using the FHD 30-60 remote control via a double acting tractor control valve.

Another option is the GSE sensor. This shows the current status of the GSE in the operating screen of the software.

ISOBUS Terminal CCI 1200

Practical test set

More safety when spreading

RAUCH PPS 5 Practical test set permits cross-distribution to be checked and corrected quickly and easily in the field. This provides even more reliability and accuracy during spreading, particularly with fertilisers of lower quality, problematic discharge properties or unknown origin.

In combination with the clear and comprehensible AXIS-CDA tuning logic, corrections are amazingly easy and secure.

PPS 5 components:

- 10 collecting trays

- 5 measuring cylinders

- 1 roller tape measure

- clear, logical operating instructions.

Limited border spreading H-Drive

No Telimat is needed with the hydraulically driven fertiliser spreaders AXIS-H 30 and 50, since the unilateral reduction in the speed of the spreading discs in combination with an adjustment of the fertiliser output point produces a sharply demarcated boundary spreading pattern. This type of border spreading is even more precise, it fulfils the requirements of the European environmental standard and is also approved under the German Fertiliser Ordinance.

- Border spreading right and left

- Border spreading at the touch of a button

- Remote-controlled switching from edge to border spreading

- Individual adjustment of the disc speed on the border side when, for instance, spreading occurs on an uphill incline or at a water ditch.

-

Ejection discs

Everything revolves around precision.

Ejection discs Working width Beschreibung S1 Working width: 12-18 m S4 Working width: 18-28 m S6 Working width: 24-36 m S8 Working width: 30-42 m S10 Working width: 36-48 m S12 Working width: 42-50 m * Coated spreader vanes with VXR plus

Technical data and equipment

| Model variant | TWS 85.1 M | TWS 85.1 H | TWS 85.1 HT |

| Basic machine | |||

| Working width [ m ] | 12 – 42 | 12 – 42 | 12 – 42 |

| Hopper volume [ l ] | 8,400 | 8,400 | 8,400 |

| Max. capacity [ kg ] | 8,160 | 8,160 | 8,160 |

| Container size [ cm ] | 350 x 230 | 350 x 230 | 350 x 230 |

| Filling height [ cm ] | 285 | 285 | 285 |

| Filling width [ cm ] | 350 | 350 | 350 |

| Empty weight [ kg ] | 3,840 | 3,840 | 3,840 |

| Track width [ cm ] | 180 x 225 | 180 x 225 | 180 x 225 |

| Tractor attachment | Drawn | Drawn | Drawn |

| Axle type | Rigid axle | Rigid axle | Rigid axle |

| Hitching | Top hitching | Top hitching | Top hitching |

| Axle load [ t ] | 10 | 10 | 10 |

| Brake | Pneumatic brake | Pneumatic brake | Pneumatic brake |

| Drive | M drive: Universal drive shaft with ratchet safety clutch 540 rpm, H drive: Hydraulic demand 45 l/min., Electrical agitator drive with auto-stop | H drive: Hydraulic demand 85 l/min., Electrical agitator drive with auto-stop | H drive: Hydraulic demand 110 l/min., Electrical agitator drive with auto-stop |

| Electrical agitator drive with auto-stop | No | Yes | Yes |

| Metering | |||

| Slide actuation/quantity regulation | EMC mass flow control | EMC mass flow control | |

| Servomotors | Slide actuation elec. Linear actuator | Slide actuation elec. HighSpeed servos | Slide actuation elec. HighSpeed servos |

| Variable Rate Control | Yes | Yes | Yes |

| Electronics | QUANTRON-A spreading system | QUANTRON-A spreading system | QUANTRON-A spreading system |

| Section control | VariSpread V8 partial width controller | VariSpread pro partial width controller | VariSpread pro partial width controller |

| Limited border spreading | Limited border spreading with GSE | Limited border spreading with GSE | Limited border spreading with GSE |

![[Translate to English:] AXIS lighting with warning signs](/fileadmin/_processed_/7/0/csm_beleuchtung-warntafel-rauch-duengerstreuer-scheibenstreuer-7185-w_177745c67e.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/0/csm_beleuchtung-warntafel-rauch-duengerstreuer-scheibenstreuer-7185-w_bff6df9b37.jpg)

![[Translate to English:] SpreadLight | AXIS](/fileadmin/_processed_/4/3/csm_spreadlight-axis-duengerstreuer-4621-w_a3cbb824b5.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/3/csm_spreadlight-axis-duengerstreuer-4621-w_0da63109cf.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/3/csm_spreadlight-axis-duengerstreuer-4999-w_ccf37814b9.jpg)

![[Translate to English:] Limited border spreading GSE AXIS/AXENT](/fileadmin/_processed_/0/5/csm_gse-30-60-rauch-duengerstreuer-scheibenstreuer-1427-w_bdb338d96c.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/5/csm_gse-30-60-rauch-duengerstreuer-scheibenstreuer-1427-w_64a3828b3c.jpg)

![[Translate to English:] Hopper cover | TWS](/fileadmin/_processed_/8/1/csm_abdeckplane-tws-rauch-duengerstreuer-grossflaechenstreuer-8953-w_a6e3c4eb31.jpg)

![[Translate to English:] Limited border spreading H-Drive](/fileadmin/_processed_/4/e/csm_grenzstreuen-axis-h-rauch-duengerstreuer-scheibenstreuer-5079-w_468590364f.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/e/csm_grenzstreuen-axis-h-rauch-duengerstreuer-scheibenstreuer-5079-w_546dc0ca29.jpg)