information material

Compact two-disc fertiliser spreader

With 100 Hz weighing technology

AXIS M 20.2 W offers professional weighing and spreading technology especially for future-oriented businesses. Due to its low filling height, AXIS M 20.2 W is ideal for filling dump trucks. With its unique performance potential, it sets new standards for professional agriculture.

Model variants AXIS M 20.2 W

| AXIS M 20.2 W | with the precise 100 Hz weighing technology |

|---|

Benefits

-

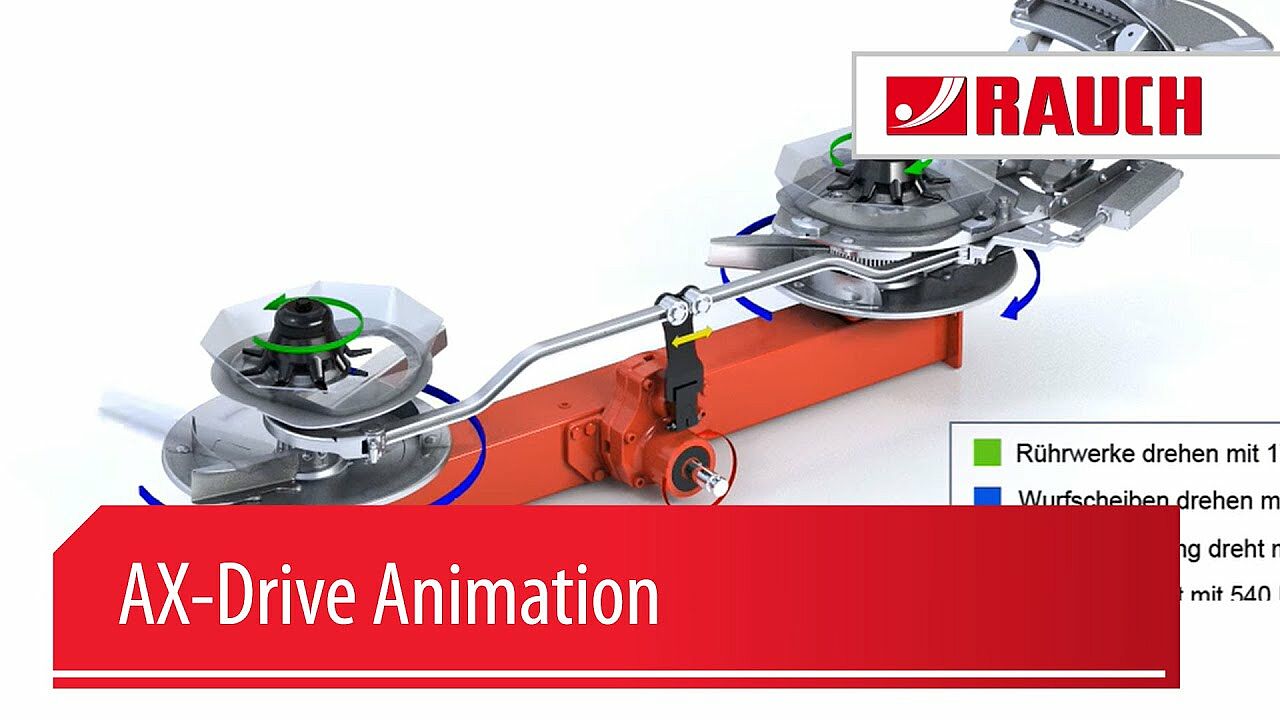

M-Drive

M-Drive: maintenance-free gearbox technology with overload protection

The innovative M-Drive for the throwing discs and the slow-running, fertilizer-friendly agitators is maintenance-free for years. All shafts and angular gears run in an oil or grease bath and are protected from fertilizer dust, dirt, moisture and mechanical damage by a robust frame construction.

.Unique in fertilizer technology, AXIS features overload protection systems that protect the entire gear unit, including the fertilizer-protecting agitators, from overload caused by jams, operator error or hard-shifting PTOs.

M-Drive performance data

.- Transmission input: PTO speed of 540 rpm

- Turntable speed: 900 rpm

- Agitator speed: 17 rpm pulsating and extremely gentle on fertilizer

AXIS M 50.2 EMC+W

- Gearbox input: PTO speed of 750 rpm

- Throwing disc speed: 900 rpm

- Stirrer speed: 17 rpm pulsating and extremely gentle on fertilizer

.

Intelligent agitator technology

.The innovative agitator drive for the slow-running, fertilizer-sparing agitators is

.

maintenance-free for years. Overload protection systems protect the entire agitator unit from overstress due to blockages.- extremely fertilizer-sponed: vibration agitator rotates at only 17 rpm

-

CDA spreading technology | manual

The coaxial metering and feed point adjustment, in short CDA spreading technology

CDA spreading technology - functionality meets elegance

The coaxial dispensing and output point, short CDA scattering technology, makes it all possible. Setting up a two-disc fertiliser spreader has never been as easy. All functions are set quickly, safely and in an ergonomically ideal position using the CDA control terminal.

- Fertiliser type and quality

- Working width

- Dispensing volume

Brilliant: An easy-to-control turn on the CDA control terminal is sufficient to quickly and safely set the fertiliser outpoint point, the fertiliser grade as well as the spreading width. For spreaders without dispensing electronics, the desired quantity to be dispensed is also adjusted here at the same time.

The big advantage: The usual procedure of setting the spreader vanes is not necessary with AXIS.

For machines without scatter computers, the spread rate setting is as simple as it is precise. Pre-selecting the quantity for demand-based, incremental dispensing starting from 3 kg/ha takes place using a large, clear scale sheet, separated for the right and left side. The volume-proportional DfC scale, exclusively from RAUCH, offers the possibility of proportionally varying the application rate quickly following the calibration test.

DfC also makes it easy to change the volume to be dispensed from one beat to another.

The clear, comprehensive fertiliser chart available on the Internet or as a smartphone app contains all the relevant setting information. Typical RAUCH: detailed data on slug pellets and seeds is also listed in the fertiliser chart

-

100 Hz weighing system

Automation, innovation and precision

The QUANTRON-E2 control terminal, in conjunction with the RAUCH weighing system, checks the application rate 100 times a second while driving. Scattering errors caused by varying flow properties of the grit or changes in speed are detected immediately and corrected automatically once every second.

Without the need for a manual calibration test, the 100 Hz weighing technology automatically optimises the quantity to be dispensed, making a decisive contribution towards greater economy and ecology in the application of valuable fertiliser granules.

When the grit is being scattered, the intelligent electronics automatically record all data and automatically ensure error-free documentation. The remaining quantity is displayed continuously.

The low centre of gravity of the AXIS M 20.2 W and 30.2 W as well as their particularly low dead weight also make it possible to use low-power tractors problem-free.

-

VariSpread V4

AXIS spreaders with QUANTRON-E2 and manual CDA output point adjustment are equipped with the VariSpread V4 4-way section control system as standard. Four sections can be realised on each side via remote-controlled adjustment of the dispensing gate positions or via application rate adjustment.

-

Perforation corrosion guarantee

AXIS fertilizer spreaders from RAUCH are characterized by a high-quality durable ProTect double powder coating.

The optimal protection against mechanical stress, UV light, salts and acids guarantees a long service life of the construction.

RAUCH provides a 6-year warranty against perforation corrosion on all AXIS fertilizer spreaders.Activate the rust-through warranty of your new AXIS fertiliser spreader within 3 months of delivery of the new machine by scanning the QR code on the warranty sticker (on the machine),

register* the serial number of your new AXIS machine and your address information in the online portal and then click on "Submit application" - it's easy!Benefit from the proverbial RAUCH quality for many years.

*Registration must be completed by the end customer within 3 months of delivery of the new machine to the end customer (proof may be required)

Tools

Accessories

Hopper cover and AP drive

The prefect protection against moisture and dirt from the tyres.

All AXIS hopper covers open over the entire filling area thanks to the high-quality "convertible-like folding" feature.

So filling can carry on, trouble-free, as usual. An opening mechanism with a long lever arm makes it easy to open and close the hopper cover.

Even with a hopper cover, the fill level can still be checked quickly and easily from the tractor cab via the window areas in the cover.

Option:

On request, the hopper cover can be operated remotely from the cab via the electric AP-Drive (only with AXIS of the .2 series with Quantron-A or ISOBUS).

Parking rollers ASR 25

Enjoy more flexibility when it comes to spreader attachments and dismantling with the large ASR 25 parking rollers. A quick-release coupling system allows the rollers to be removed at any time or mounted in transport position.

Access ladder AS-XL-25

The collapsible ladder enables easy access to the container. Only for AXIS 30.2 / 50.2 in conjunction with wide XL attachments.

AXIS 50.2 generally comes with a ladder (left) as standard.

Bei AXIS 50.2 ist eine Aufstiegsleiter (links) im Serienumfang enthalten.

AXIS lighting with warning signs

High-quality LED headlights, integrated in the warning signs, ensure more safety on the road.

Front lighting

High-quality LED headlights, integrated in the warning signs, provide a good view of the tractor.

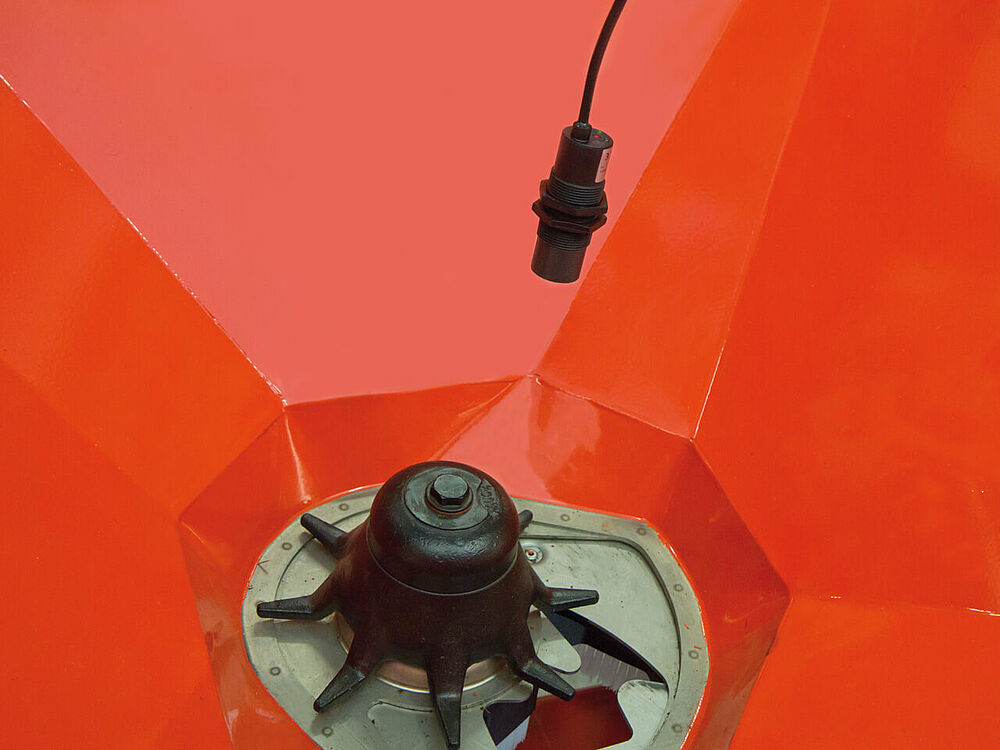

Level sensors | AXIS

For each AXIS with electronics one level sensor can be optionally fitted to the filling sieve per container side. These sensors give off a warning in the display should the level on the respective side get too low. This accessory is particularly interesting for machines without remaining quantity scale or for spreaders with section control, which work in a very one-sided manner, and it also helps to avoid flaws.

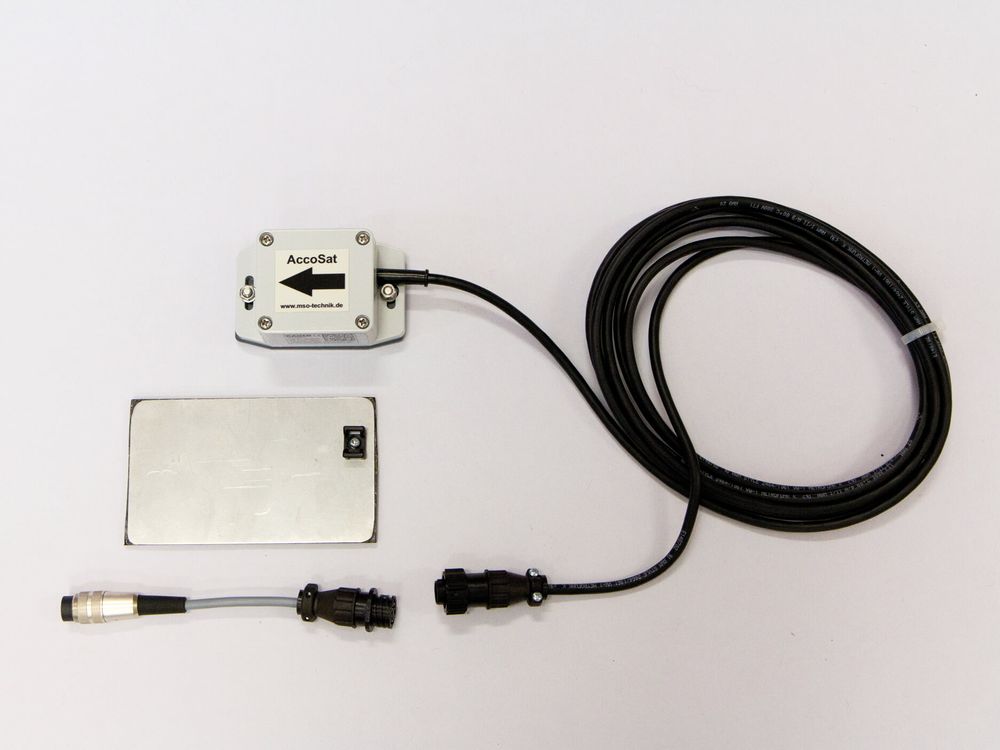

GPS speed sensor

In order to be able to regulate spreading according to the driving speed, the QUANTRON-A and QUANTRON-K2 scatter computers, and the ISOBUS display all require a speed signal. This usually comes via the 7-pin signal socket or the ISOBUS from the tractor unit. If the tractor itself is not equipped with this signal, either a wheel sensor must be retrofitted or you can use this GPS speed sensor.

A GPS signal in combination with an acceleration sensor generates a high-precision speed signal. This is especially recommended if the spreader is used in combination with several tractors or is also shared by different companies.

Another great advantage of this is that the slip of the tractor tyres in wet conditions or slopes does not matter and does not adversely affect the spreading result.

Limited border spreading GSE AXIS/AXENT

The GSE 30 and GSE 60 enable sharp-edged border spreading on the left and right side directly on the field boundary with half-side spreading. The distance to the border can be varied between 0 to 3 m. GSE 30 is the thrower shield for AXIS 20.2 / 30.2. GSE 60 is suitable for use with AXIS 50.2 and AXENT.

Optionally, GSE 30/60 can be remotely controlled hydraulically using the FHD 30-60 remote control via a double acting tractor control valve.

Another option is the GSE sensor. This shows the current status of the GSE in the operating screen of the software.

Limited border spreading Telimat AXIS

TELIMAT T25/T50

TELIMAT enables precise, hydraulically remote-controlled edge and border spreading right from the first tracks. The double-adjustable spreading compartments redirect the fertiliser to fulfil the requirements of the European environmental standard.

Without the need for stopping and dismounting, the Telimat T25 swings up and down on the AXIS 20 and 30 via a single-acting tractor control valve. AXIS M 50.2 W ISOBUS is equipped with a TELIMAT T50 remote control as standard.

GPS control with CCI 800

In order to use the QUANTRON-A to automatically switch part-width sections and headlands via GPS or to scatter application maps, the QUANTRON-A is connected to the CCI.800 terminal via a serial interface.

In this case, the CCI.800 is not used as an ISOBUS terminal, but as a GPS terminal that, in combination with a GPS receiver, switches part-width sections via SectionControl or processes application maps via the TaskController.

Practical test set

More safety when spreading

RAUCH PPS 5 Practical test set permits cross-distribution to be checked and corrected quickly and easily in the field. This provides even more reliability and accuracy during spreading, particularly with fertilisers of lower quality, problematic discharge properties or unknown origin.

In combination with the clear and comprehensible AXIS-CDA tuning logic, corrections are amazingly easy and secure.

PPS 5 components:

- 10 collecting trays

- 5 measuring cylinders

- 1 roller tape measure

- clear, logical operating instructions.

Rear view camera

The RAUCH rear-view camera for RAUCH ISOBUS fertiliser spreaders also provides a good view to the rear, even on tall machines. This increases work safety when manoeuvring and also when spreading. The robust camera body is attached to the rear of the spreader. A protective plate prevents radiation and reduces the dirtying of the optics. The direction of the camera can be adjusted depending on the application.

The rear-view camera is compatible with the RAUCH ISOBUS universal terminals. Moreover, the camera can be connected to all terminals that have an AEF-compliant video input.

The rear-view camera is available for use with AXIS-ISOBUS, AXENT and AGT.

Dirt deflector with quick release fastener

A practical idea makes it all the way to series production. With the assembling tool located on the spreader, the three attachment points of the mud flaps can be released quickly and easily with a quarter turn. So cleaning the machine quickly and carefully is a snap.

SpreadLight | AXIS

Modern GPS-controlled OptiPoint headland management systems and VariSpread section controls make precise fertiliser spreading possible - even at night. So far, however, it has been very difficult for the driver to visually check the individual spreader functions while spreading in the dark. In addition, obstacles in the spreading area pose a risk at night.

Thanks to the SpreadLight work lights, RAUCH has solved these problems. Modern, powerful LED work lights directly above the two spreader discs of the fertiliser spreader illuminate the spread fans on the left and right side.

The driver has the spread fan in full view thanks to SpreadLight. Possible incorrect settings or clogging at the dispensing gates are recognised immediately. Moreover, the operator can respond more quickly to difficult-to-detect obstacles or danger spots in the outer spreading area in the dark, especially when it comes to wide spreading widths.</p<p>Unlike the tractor's work lights, SpreadLight is specifically aimed at the spreading fan. The fertiliser granules thereby reflect the intensive LED light.

As simple as it is convenient, SpreadLight is remotely controlled by the ISOBUS terminal via a touchscreen. The operator can choose whether the headlamps are permanently lit or automatically switch off and on in the headland in order to avoid blinding oncoming traffic on the road. SpreadLight can be retrofitted as an option for all mechanical and hydraulically driven RAUCH AXIS.2 ISOBUS fertiliser spreaders.

Telimat sensor

The optional AXIS Telimat sensor shows in the display of the QUANTRON-A or the ISOBUS terminal whether the Telimat thrower shield is in the ready position. It happens again and again that not only smartphone-happy farmers forget to raise the Telimat again after limited border spreading, thereby causing errors in the spreading results. Just one look at the display and you will be reminded of the Telimat's position.

-

Ejection discs

Everything revolves around precision.

Ejection discs Working width Beschreibung S2 Working width: 12-18m S4 Working width: 18-28 m S6 Working width: 24-36 m * Coated spreader vanes with VXR plus

-

Hopper extensions

The flexible attachment system enables optimum adjustment of the hopper volume.

Technical data and equipment

| Model variant | AXIS M 20.2 W |

| Basic machine | |

| Working width [ m ] | 12 – 36 |

| Hopper volume [ l ] | 1,000 |

| Max. capacity [ kg ] | 2,300 |

| Container size [ cm ] | 240 x 130 |

| Filling height [ cm ] | 95 |

| Filling width [ cm ] | 230 |

| Empty weight [ kg ] | 355 |

| Tractor attachment | Three point category II/III |

| Drive | M drive: Universal drive shaft with ratchet safety clutch 540 rpm |

| Metering | |

| Slide actuation/quantity regulation | Mass flow control via scales |

| Servomotors | Slide actuation elec. Linear actuator |

| Variable Rate Control | Yes |

| Electronics | QUANTRON-E2 spreading system |

| Section control | VariSpread V4 partial width controller |

| Limited border spreading | Limited border spreading with TELIMAT, Limited border spreading with GSE |

![[Translate to English:] AXIS M 20.2 W](/fileadmin/duengerstreuer/axis-m-20-2-w/axis-m-20-2-w-rauch-duengerstreuer-scheibenstreuer-8390-h.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/8/csm_RAUCH_Durchrostungsgarantie_w_1e9aac26db.jpg)

![[Translate to English:] Hopper cover and AP drive](/fileadmin/_processed_/f/5/csm_abdeckplane-rauch-duengerstreuer-scheibenstreuer-0606-w_59cba0b6ff.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/5/csm_abdeckplane-rauch-duengerstreuer-scheibenstreuer-0606-w_5e22081567.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/2/csm_axis-m-30-2-D-rauch-duengerstreuer-scheibenstreuer-8736-w_a5072e00e4.jpg)

![[Translate to English:] AXIS lighting with warning signs](/fileadmin/_processed_/7/0/csm_beleuchtung-warntafel-rauch-duengerstreuer-scheibenstreuer-7185-w_177745c67e.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/0/csm_beleuchtung-warntafel-rauch-duengerstreuer-scheibenstreuer-7185-w_bff6df9b37.jpg)

![[Translate to English:] Front lighting](/fileadmin/_processed_/5/3/csm_beleuchtung-vorne-rauch-duengerstreuer-scheibenstreuer-25-w_fe407d6b4a.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/3/csm_beleuchtung-vorne-rauch-duengerstreuer-scheibenstreuer-25-w_ef57112725.jpg)

![[Translate to English:] Limited border spreading GSE AXIS/AXENT](/fileadmin/_processed_/0/5/csm_gse-30-60-rauch-duengerstreuer-scheibenstreuer-1427-w_bdb338d96c.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/5/csm_gse-30-60-rauch-duengerstreuer-scheibenstreuer-1427-w_64a3828b3c.jpg)

![[Translate to English:] SpreadLight | AXIS](/fileadmin/_processed_/4/3/csm_spreadlight-axis-duengerstreuer-4621-w_a3cbb824b5.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/3/csm_spreadlight-axis-duengerstreuer-4621-w_0da63109cf.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/3/csm_spreadlight-axis-duengerstreuer-4999-w_ccf37814b9.jpg)

![[Translate to English:] Telimat sensor](/fileadmin/_processed_/1/e/csm_telimatsensor-rauch-duengerstreuer-scheibenstreuer-5597-w_2b9de0b100.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/e/csm_telimatsensor-rauch-duengerstreuer-scheibenstreuer-5597-w_3a089ae7cb.jpg)