AXEO 2.1 - winter service made easy

The compact AXEO 2.1 winter spreader offers professional spreading technology for municipal vehicles of the lower performance class. Whether salt, grit, sand or fertiliser, AXEO sets new standards in distribution accuracy, intuitive ease of use and flexibility throughout the year.

Model variants AXEO 2.1

| AXEO 2.1 H | Driven by cardan shaft, open / close gate hydraulically via a single-acting control unit |

|---|---|

| AXEO 2.1 H-100 | Driven by 100 cm³ hydraulic motor, open / close gate hydraulically via a single-acting control unit |

| AXEO 2.1 C | Driven by cardan shaft, open / close gate electrically via remote control with E-Click (12 V, 3-pin power socket, cable length 5 m) |

| AXEO 2.1 C-100 | Driven by 100 cm³ hydraulic motor, open / close gate electrically via remote control with E-Click (12 V, 3-pin power socket, cable length 5 m) |

| AXEO 2.1 Q | Driven by cardan shaft, open / close gate and control spread rate electronically via QUANTRON-K2 scatter computer, incl. vehicle speed sensor installation kit |

| AXEO 2.1 Q-100 | Driven by 100 cm³ hydraulic motor, open / close gate and control spread rate electronically via QUANTRON-K2 scatter computer, incl. vehicle speed sensor installation kit |

| AXEO 2.1 Q-100 HydroControl | Driven by 100 cm³ hydraulic motor, open / close gate and control spread rate electronically via QUANTRON-K2 scatter computer with automatic activation / deactivation of the agitator, incl. vehicle speed sensor installation kit |

![[Translate to English:] [Translate to English:]](/fileadmin/winterdienst/AXEO_2-1_rauch_Scheibenstreuer_4074_w_02.png)

Benefits

-

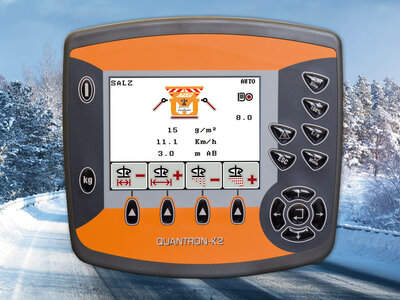

QUANTRON-K2

Metering electronics for high demands

QUANTRON-K2 is the electronic spread rate system for the whole AXEO product family.

With the new QUANTRON-K2 electronic spread rate control system, a new technology is being deployed in the area of municipal winter service. Modern electronics greatly increase the ease of use and thus optimise winter service in terms of economy and environmental friendliness.

Intelligent technology for more efficiency and comfort

-

VariSpread | AXEO

Flexible, remote-controlled adjustment of the spreading range

An additional, electrically operated VariSpread gate in the dispensing gate opening changes how the spreading material is discharged onto the spreader disc in three positions. As a result, the spreading width can be elegantly varied on one side in the direction of travel as anticipated. At the same time, the VariSpread gate adjusts the spreading rate to match the set spreading width. The intelligent, automatic interaction with the spreading width limiter achieves 5 sections on the right side with extreme precision.

The advantages of VariSpread:

The spreading width and spread rate can be adjusted remotely from the QUANTRON-K2 control panel at the touch of a button. The sections are automatically adjusted precisely in five directions in the right direction of travel. The spreading precision on the opposite side remains unaffected. VariSpread increases spreading efficiency in wedge-shaped areas and bottlenecks by 25% or more over conventional spread width limiters. Environmental pollution caused by overdosing on the reduced side is avoided right from the start. VariSpread increases economic efficiency and protects the environment.

-

E-Click | AXEO

Increased operating comfort for winter services

The electric gate version C with the comfortable E-Click terminal for the entire AXEO winter service spreader series opens up new fields of application, especially for municipal vehicles with few or no hydraulic connections.

What's special about E-Click: Both the electrical dispensing gate and the optional electrical spreading width limiter can be conveniently activated via a toggle switch on the operator terminal in the cab. Perfectly-designed ergonomics make work easier when winter hits hard. A control diode displays the current gate position. This greatly minimises operating errors.

The E-Click control terminal is elegantly connected to the AXEO winter service spreader by a cable. The need to connect hydraulic hoses is thus completely eliminated. High-quality, dust and splash-proof actuators ensure a high level of operating comfort, ensured functionality and a long service life for your investment.

-

Online GPS documentation

Online GPS documentation for municipal spreaders

GPS.at, well-known as an expert in terms of GPS tracking, offers a GPS telematics box, which detects the current position of the vehicle via GPS, records the data such as spread rate and spreading width from the winter spreader's scatter computer, and sends it via a GSM module to the internet-based GPS Fleet Software. Thus, municipalities and service providers can fulfil their documentation obligations and prove exactly when, where and how much material they distributed. Moreover, a combination with a working position sensor for snow ploughs is possible.

The Fleet Box is installed in the tractor and connected to the QUANTRON-K2 scatter computer by cable for AXEO or QUANTRON-A from UKS. The scatter computer transmits the data

- Scatter On / Off

- Spreading volume in g/m²

- Spreading width (m)

to the Fleetbox, which transmits it in combination with the GPS position and time to the Fleet Software and displays it on the Internet or on the app in real time. So, on the one hand, you can see online where the spreaders are and what they are currently up to and, on the other hand, you can subsequently and accurately document when and how the spreading was done.

-

HydroControl

Intelligent drive model - HydroControl

The AXEO-Q HydroControl with hydraulic spreading disc and agitator drive allows the spreading width to be adjusted remotely thanks to the perfect interaction between the target spreader disc speed and the spreading width limiter. The special thing about it: If the tractor stops or starts, the agitator and the spreader disc are automatically switched off or on. Not only does this protect the valuable material to be spread, it also increases the spreading precision. This, in turn, significantly increases the efficiency and profitability of the application. At the same time, the driver enjoys more comfort while the environment is protected.

Elegant and simple, all spreader functions are set directly via the control panel. The harmonious combination of the precise, speed-dependent QUANTRON-K2 material dispenser and the intelligent HydroControl drive technology opens up new dimensions of efficiency, cost-effectiveness and ease of use for AXEO.

With the optional remote-controlled spreading width limiter, the spreading width on both sides can be varied separately or together and from 0.8 m up to 8 m at the push of a button.

-

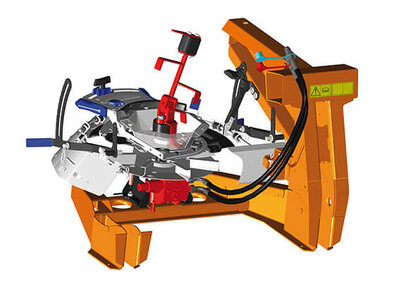

CDA spreading technology | AXEO

remote controlled, coaxial dosing and task point adjustment

AXEO puts performance on the road

The patented AXEO-CDA spreading technology consists of a spreader disc with eight spreader vanes (speed of 230 rpm) as well as a large and intelligently-designed dispensing gate opening, which is located in the rotatable container floor. This sophisticated system achieves a uniform transverse and longitudinal distribution with a steeply sloping drop-off at the side, a so-called "trapezoidal sweep", even at high operating speeds.

Unique feature: Elegance, convenience and safety are what you get since both the stray symmetry and the spread rate are easily and quickly adjusted on the central CDA control terminal.

Save costs and protect the environment

Thanks to its exact quantity dispensing and precise adaptation to the ideal spreading width, AXEO can save up to 30% of spreading material. Added to this are significantly lower costs to remove area damage, such as tree and plant debris.

-

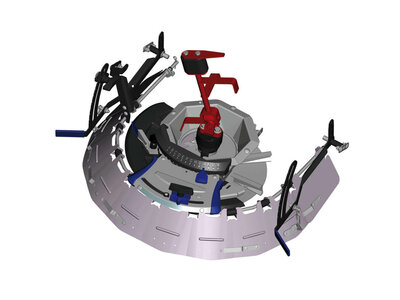

Agitators | AXEO

The right agitator makes the difference

Grit-friendly and safe

The innovative AXEO agitator concept consistently takes into account the different requirements of individual spreading materials.

- RWK AX 140 for granulated fertilisers

- RWK AX 160 for grit

- RWK AX 165 for high-grade grit

- RWK AX 180 for sand/moist salt

- RWK AX 220 for dry salt (bags/silo)

- RWK AX 240 for grit-salt mixtures

Result: Smooth and trouble-free spreading even with problematic spreading properties.

Typical RAUCH: The AXEO agitators are made of highly wear-resistant materials and can be replaced without any tools.

RAUCH winter spreader for year-round use

With the right agitators, not only can RAUCH AXEO spreaders be used with extreme efficiency in winter services. The new AXEO system agitator also offers perfect solutions for professional summer use.

Fertilisers and even fine seeds can be spread precisely with the system agitators. On the one hand, the innovative agitators protect the valuable spreading material. On the other hand, the ingenious agitator heads achieve a trouble-free, constant feed of the material to be spread. In combination with the exact CDA spreading technology, AXEO enables extreme dispensing and distribution accuracy for sand, salt, grit, as well as fertilisers and fine seed.

Typical RAUCH: Thanks to the convenient quick-change system, any agitator can be replaced quickly and easily. The great advantage is that winter spreaders can be used more efficiently throughout the year, thereby increasing the efficiency and profitability of the spreading technology used.

Tools

Accessories

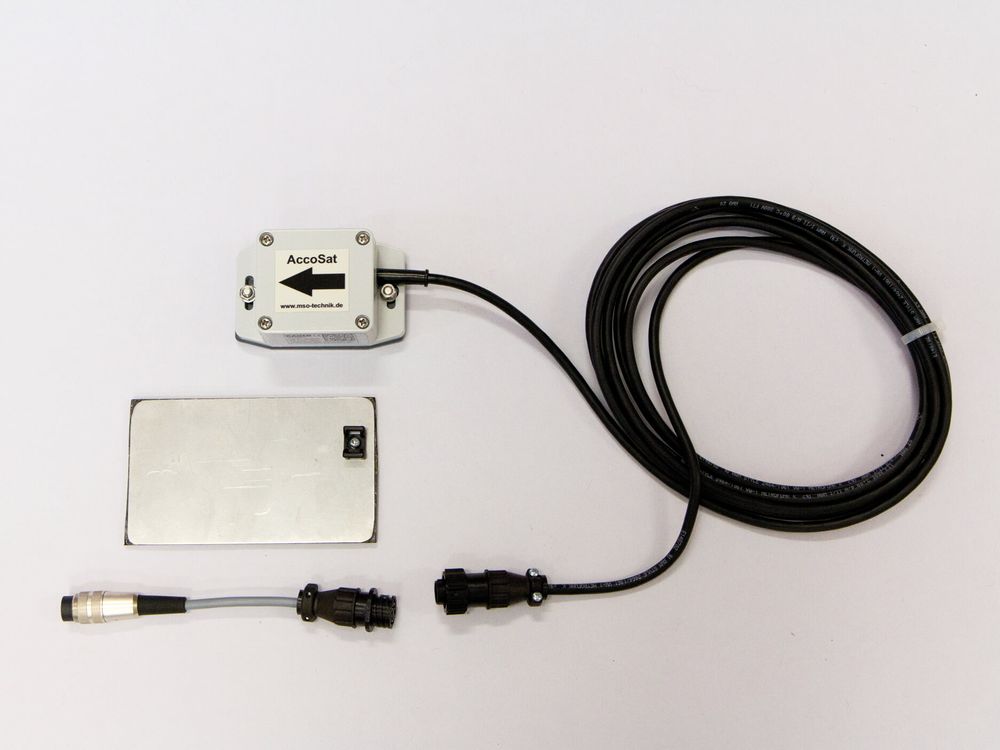

GPS speed sensor

In order to be able to regulate spreading according to the driving speed, the QUANTRON-A and QUANTRON-K2 scatter computers, and the ISOBUS display all require a speed signal. This usually comes via the 7-pin signal socket or the ISOBUS from the tractor unit. If the tractor itself is not equipped with this signal, either a wheel sensor must be retrofitted or you can use this GPS speed sensor.

A GPS signal in combination with an acceleration sensor generates a high-precision speed signal. This is especially recommended if the spreader is used in combination with several tractors or is also shared by different companies.

Another great advantage of this is that the slip of the tractor tyres in wet conditions or slopes does not matter and does not adversely affect the spreading result.

Lighting without warning sign

Lighting ensure more safety on the road.

Spreader apron

Spreader apron for protection against splashing water

Electrical remote control

Electric remote control for joint adjustment of the spreading width limitation left and right.

Hopper cover | AXEO 2.1

The optimal protection against moisture. Can be easily folded upwards for easy filling.

SpreadLight | AXEO

The professional RAUCH AXEO winter service spreader facilitates safe and precise spreading in the darker months thanks to the new SpreadLight. On each side of the spreader, a highly efficient SpreadLight LED floodlight is precisely aligned with the spread fan. The intense LED light is reflected by materials such as salt, sand and grit in an ideal way. As a result, the driver has the entire spread fan in full view, even in the dark.

Thanks to the remote-controlled RAUCH spreading width limiter or the precise VariSpread section control, SpreadLight can be perfectly adapted to the boundary of the road or parking spaces within a few seconds thanks. So parked cars won't get sprayed and the unwanted spraying of grit in green areas is efficiently avoided.

AXEO spreaders with the QUANTRON-K2 dispensing electronics can be equipped with the new and efficient SpreadLight feature.

(can be retrofitted from serial number 19-016783, from software Version 2.00.00)

-

Hopper extensions

The flexible attachment system enables optimum adjustment of the hopper volume.

Hopper extension AX 100 Additional volume [ l ] 100 Total volume [ l ] 350 Additional filling height [ cm ] 14 Filling width [ cm ] 88 Additional weight [ kg ] 14

Technical data and equipment

| Model variant | AXEO 2.1 H | AXEO 2.1 H-100 | AXEO 2.1 C | AXEO 2.1 C-100 | AXEO 2.1 Q | AXEO 2.1 Q-100 | AXEO 2.1 Q-100 HydroControl |

| Basic machine | |||||||

| Working width [ m ] | 1 – 8 | 1 – 8 | 1 – 8 | 1 – 8 | 1 – 8 | 1 – 8 | 1 – 8 |

| Hopper volume [ l ] | 250 | 250 | 250 | 250 | 250 | 250 | 250 |

| Max. capacity [ kg ] | 800 | 800 | 800 | 800 | 800 | 800 | 800 |

| Container size [ cm ] | 100 x 87 | 100 x 87 | 100 x 87 | 100 x 87 | 100 x 87 | 100 x 87 | 100 x 87 |

| Filling height [ cm ] | 96 | 96 | 96 | 96 | 96 | 96 | 96 |

| Filling width [ cm ] | 88 | 88 | 88 | 88 | 88 | 88 | 88 |

| Empty weight [ kg ] | 130 | 130 | 130 | 130 | 130 | 130 | 130 |

| Tractor attachment | Three-point category I | Three-point category I | Three-point category I | Three-point category I | Three-point category I | Three-point category I | Three-point category I |

| Drive | M drive: Universal drive shaft with shear bolt 540 rpm | H drive: Hydraulic demand 25 l/min. | M drive: Universal drive shaft with shear bolt 540 rpm | H drive: Hydraulic demand 25 l/min. | M drive: Universal drive shaft with shear bolt 540 rpm | H drive: Hydraulic demand 25 l/min. | H drive: Hydraulic demand 25 l/min. |

| Metering | |||||||

| Slide actuation/quantity regulation | Hydraulic metering slide | Hydraulic metering slide | Electrical metering slide | Electrical metering slide | Electronic metering slide without mass flow control | Electronic metering slide without mass flow control | Electronic metering slide without mass flow control |

| Servomotors | - | - | Slide actuation elec. Linear actuator | Slide actuation elec. Linear actuator | Slide actuation elec. Linear actuator | Slide actuation elec. Linear actuator | Slide actuation elec. Linear actuator |

| Electronics | - | - | EN- Bedienung E-Click | EN- Bedienung E-Click | QUANTRON-K2 spreading system | QUANTRON-K2 spreading system | QUANTRON-K2 spreading system |

| Section control | None | None | None | None | VariSpread half-side slide | VariSpread half-side slide | VariSpread half-side slide |

![[Translate to English:] AXEO 2.1](/fileadmin/winterdienst/axeo/AXEO_2_1_0281_Rauch_Winterdienst_Scheibenstreuer_h.jpg)

![[Translate to English:] Lighting without warning sign](/fileadmin/_processed_/b/a/csm_Beleuchtung_ohne_Warntafel_rauch_1989_w_eb5a90c3e2.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/a/csm_Beleuchtung_ohne_Warntafel_rauch_1989_w_1675348020.png)

![[Translate to English:] Spreader apron](/fileadmin/_processed_/e/8/csm_Streuschuerze_rauch_5542_w_34ce460d67.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/e/8/csm_Streuschuerze_rauch_5542_w_e20aed2bb0.png)

![[Translate to English:] Electrical remote control](/fileadmin/_processed_/6/a/csm_elektrische-fernbedienung-rauch-kommunalstreuer-winterdienst-6204-w_1dac9ed779.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/a/csm_elektrische-fernbedienung-rauch-kommunalstreuer-winterdienst-6204-w_a09d2d7a32.jpg)

![[Translate to English:] SpreadLight | AXEO](/fileadmin/_processed_/b/3/csm_axeo-spreadlight-rauch-kommunalstreuer-winterdienst-w_3ae7f023f4.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/3/csm_axeo-spreadlight-rauch-kommunalstreuer-winterdienst-w_6b738a307a.jpg)