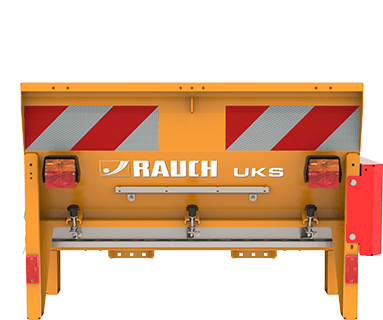

UKS 120 - the professional for pavements and parks

The UKS is characterised by problem-free metering and spreading of all known gritting materials, even those with problematic flow properties. Thanks to the low-energy, falling distribution, the grit is always deposited in the desired area.

Advantage: The grit is effectively prevented from illuminating parked cars or entering sensitive areas.

Model variants UKS 120

| UKS 120 | Drive with cardan shaft |

|---|---|

| UKS 120 hydraulic motor | Drive with hydraulic motor |

| UKS 120 Q | Drive with hydraulic motor, open/close slider and electronic spread rate control via QUANTRON-A spreading computer, including installation kit for forward speed sensor |

Benefits

-

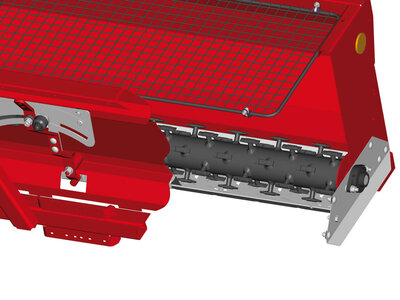

Rubber finger roller | patented

The unique agitator shaft with flexible agitator fingers feeds the spreading material to the metering slides across the entire spreading width and ensures a trouble-free flow of all known spreading materials, even those with problematic flow properties.

Advantage with hydraulic drive: with an optional flow control valve, the agitator shaft speed can be optimally adjusted to the spreading material.

-

UKS slider

The one-handed operation ensures quick opening and closing of the dosing slide. The metering quantity is preselected steplessly on a large scale. Optionally, the electric remote control for opening and closing allows the spread rate to be continuously reduced during spreading work.

Remote controls for the metering slides:

- MFB 6 (push-pull cable)

- EF 25 (12V) electric remote control

-

Online GPS documentation

Online GPS documentation for winter service

GPS.at – known as an expert in GPS tracking – offers a GPS telematics box that determines the vehicle's current position via GPS, records data such as spreading quantity and working width from the winter service spreader’s control system, and transmits it via a GSM module to the internet-based GPS Fleet Software. This allows municipalities and service providers to fulfill their documentation obligations and accurately prove when, where, and how much de-icing material has been spread. A combination with a working position sensor for the snowplow is also possible.

The Fleet Box is installed in the tractor and connected via cable to the QUANTRON-K2 spreader control system for AXEO or QUANTRON-A from UKS. The spreader control system transmits the data:

- Spreading On/Off

- Spreading quantity g/m²

- Spreading width m

to the Fleet Box, which combines this data with GPS position and time, transmits it to the Fleet Software, and displays it in real-time on the internet or in the app. This allows users to see online where the spreading vehicles are and what they are doing, as well as to retrospectively document exactly when and how spreading was performed.

-

QUANTRON-A | UKS

The electronics think for themselves

Precise: The spreading computer automatically adjusts the correct spread rate depending on the tractor's forward speed.

Convenient: The desired spread rate is simply entered into the spreader computer and can be adjusted up or down in stages at the touch of a button while driving - just as the weather requires.

Clever: If the tractor stops, the slider closes automatically. When the tractor starts up again, the slider opens again.

Intelligent: Special spreading button simulates the speed for approaching junctions.

Practical: A simulated speed can be stored in order to have the full spread rate right from the start. -

Folding stainless steel container base

The container base tray, including the dosing slides, is made entirely of stainless steel. The entire container base can be folded down in just a few simple steps. This makes it easier to empty residual quantities and creates plenty of space for quick and easy cleaning.

Tools

Accessories

Lighting without warning sign

Lighting ensure more safety on the road.

Level sensor | UKS

An optimum overview of the remaining quantity can be displayed on the UKS via the level sensor. The sensors give off a warning in the display should the level get too low.

Hopper cover | UKS

Optimum protection against humidity and dirt for grit, sand and salt.

Mechanical remote control

Push-pull cable with adjustment lever and mounting parts

Electrical remote control

Electric remote control for joint adjustment of the spreading width limitation left and right.

-

Hopper extensions

The flexible attachment system enables optimum adjustment of the hopper volume.

Hopper extension Extension UKS 120 Additional volume [ l ] 100 Total volume [ l ] 340 Additional filling height [ cm ] 15 Filling width [ cm ] 130 Additional weight [ kg ] 18

Technical data and equipment

| Model variant | UKS 120 | UKS 120 hydraulic motor | UKS 120 Q |

| Basic machine | |||

| Working width [ m ] | 1.2 | 1.2 | 1.2 |

| Hopper volume [ l ] | 240 | 240 | 240 |

| Max. capacity [ kg ] | 500 | 500 | 500 |

| Container size [ cm ] | 138 x 70 | 138 x 70 | 138 x 70 |

| Filling height [ cm ] | 75 | 75 | 75 |

| Filling width [ cm ] | 130 | 130 | 130 |

| Empty weight [ kg ] | 130 | 130 | 130 |

| Tractor attachment | Three-point category I | Three-point category I | Three-point category I |

| Drive | M drive: Universal drive shaft with shear bolt 540 rpm | H drive: Hydraulic demand 25 l/min. | H drive: Hydraulic demand 25 l/min. |

| Metering | |||

| Slide actuation/quantity regulation | Electrical metering slide, Mechanical metering slide | Electrical metering slide, Mechanical metering slide | Electronic metering slide without mass flow control |

| Servomotors | - | - | Slide actuation elec. Linear actuator |

| Electronics | - | - | QUANTRON-A spreading system |

| Limited border spreading | Limited border spreading with fixed working width | Limited border spreading with fixed working width | Limited border spreading with fixed working width |

![[Translate to English:] Lighting without warning sign](/fileadmin/_processed_/b/a/csm_Beleuchtung_ohne_Warntafel_rauch_1989_w_eb5a90c3e2.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/a/csm_Beleuchtung_ohne_Warntafel_rauch_1989_w_1675348020.png)

![[Translate to English:] Level sensor | UKS](/fileadmin/_processed_/3/2/csm_leermeldesensor-rauch-duengerstreuer-scheibenstreuer-8219-w_c0717e7813.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/3/2/csm_leermeldesensor-rauch-duengerstreuer-scheibenstreuer-8219-w_267ca94b36.jpg)

![[Translate to English:] Hopper cover | UKS](/fileadmin/_processed_/8/9/csm_uks-100-0424-rauch-winterdienst-w_5bc45039af.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/8/9/csm_uks-100-0424-rauch-winterdienst-w_447a035484.jpg)

![[Translate to English:] Mechanical remote control](/fileadmin/_processed_/2/3/csm_mech-fernbed-rauch-kommunalstreuer-winterdienst-mfb1-6205-w_4c34b666a7.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/2/3/csm_mech-fernbed-rauch-kommunalstreuer-winterdienst-mfb1-6205-w_ba072c82db.jpg)

![[Translate to English:] Electrical remote control](/fileadmin/_processed_/6/a/csm_elektrische-fernbedienung-rauch-kommunalstreuer-winterdienst-6204-w_1dac9ed779.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/a/csm_elektrische-fernbedienung-rauch-kommunalstreuer-winterdienst-6204-w_a09d2d7a32.jpg)