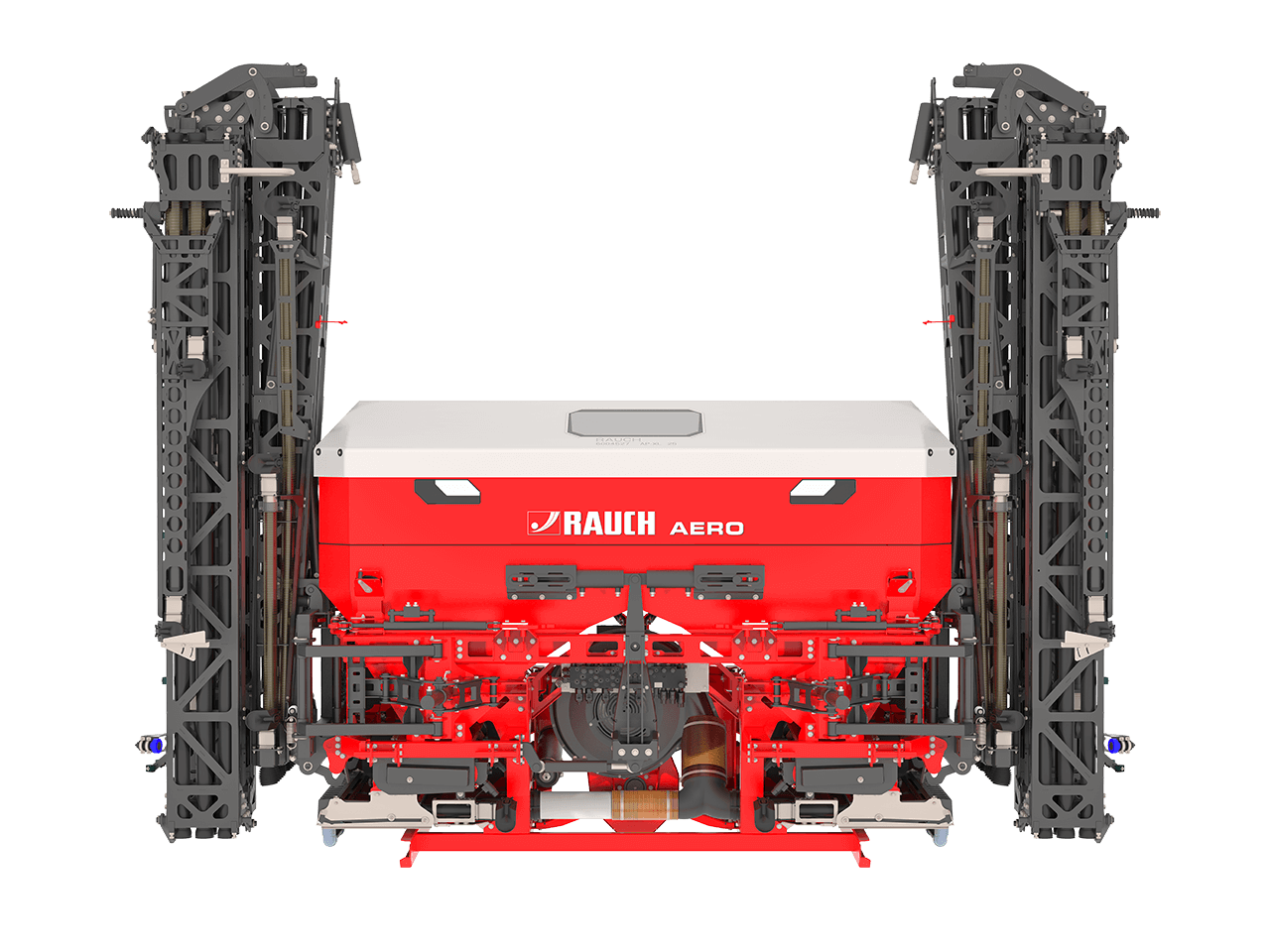

AERO 32.1

Precise pneumatic fertiliser spreader

A new level of fertiliser spreading technology:

Impact meets precision, even for fertiliser with difficult flight qualities: that’s the advantage of RAUCH's pneumatic fertiliser spreader. AERO was designed for use where maximum precision, super economic efficiency and high impact are front and centre.

AERO even allows quantity dosing for every partial width, which means a variable application rate for small spaces. Precise fertilisation of different sections takes it to the next level.

Reap the benefits of AERO!

- Precise fertilisation, even with mixed fertilisers and those with difficult flight qualities such as ammonium sulphate or urea

- Accurate boundary spreading means 100% fertiliser right to the last row without losing it on the way there

- No matter the weather – AERO spreads precisely, even in windy conditions

- Efficiently spread manure to every corner without doubling up, ideal connection in headlands

Model variants AERO 32.1

| AERO 32.1 | 24 m | Pneumatic fertilizer spreader with 24 m working width |

|---|---|

| AERO 32.1 | 27 m | Pneumatic fertilizer spreader with 27 m working width |

| AERO 32.1 | 28 m | Pneumatic fertilizer spreader with 28 m working width |

| AERO 32.1 | 30 m | Pneumatic fertilizer spreader with 30 m working width |

Benefits

-

ISOBUS

Synergien nutzen - Effizienz steigern

Innovative RAUCH ISOBUS technology for the ISOBUS fertiliser spreader allows you to use your existing and familiar ISOBUS control panels from a wide range of suppliers and machines.

-

MultiRate 4

The innovative technology of the new hydraulically driven MultiRate metering units allows a separate spread rate for each of the six boom sections. This allows application maps with an even more precise application rate.

-

100 Hz weighing system

Automation, innovation and precision

The QUANTRON-E2 control terminal, in conjunction with the RAUCH weighing system, checks the application rate 100 times a second while driving. Scattering errors caused by varying flow properties of the grit or changes in speed are detected immediately and corrected automatically once every second.

Without the need for a manual calibration test, the 100 Hz weighing technology automatically optimises the quantity to be dispensed, making a decisive contribution towards greater economy and ecology in the application of valuable fertiliser granules.

When the grit is being scattered, the intelligent electronics automatically record all data and automatically ensure error-free documentation. The remaining quantity is displayed continuously.

The low centre of gravity of the AXIS M 20.2 W and 30.2 W as well as their particularly low dead weight also make it possible to use low-power tractors problem-free.

Tools

Accessories

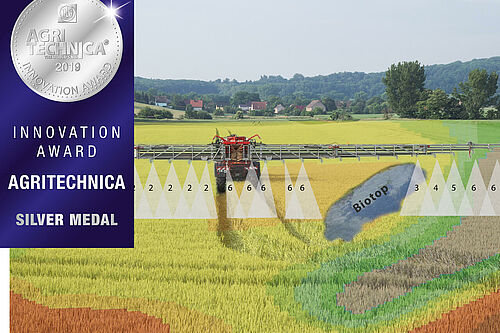

MultiRate

The MultiRate metering system for pneumatic fertiliser spreaders is the first metering and distribution system worldwide for providing exact plant nutrition over small areas. MultiRate allows a total of 30 spreading sections to be switched on an off individually.

The application rate can be individually regulated in parallel for each section. This allows fertiliser savings of up to 23% and achieves significant yield improvements.

More information about MultiRate can be found in the press release

ISOBUS Terminal CCI 1200

Fine metering shafts

With the fine metering shafts (option), very small quantities of slug pellets or fine seeds can be precisely distributed.

Dirt deflector with quick release fastener

A practical idea makes it all the way to series production. With the assembling tool located on the spreader, the three attachment points of the mud flaps can be released quickly and easily with a quarter turn. So cleaning the machine quickly and carefully is a snap.

-

Hopper extensions

The flexible attachment system enables optimum adjustment of the hopper volume.

Hopper extension AE1300 Additional volume [ l ] 1,300 Total volume [ l ] 3,200 Additional filling height [ cm ] 40 Filling width [ cm ] 280 Additional weight [ kg ] 72

Technical data and equipment

| Model variant | AERO 32.1 | 24 m | AERO 32.1 | 27 m | AERO 32.1 | 28 m | AERO 32.1 | 30 m |

| Basic machine | ||||

| Working width [ m ] | 24 – 30 | 24 – 30 | 24 – 30 | 24 – 30 |

| Hopper volume [ l ] | 1,900 | 1,900 | 1,900 | 1,900 |

| Max. capacity [ kg ] | 3,200 | 3,200 | 3,200 | 3,200 |

| Container size [ cm ] | 280 x 130 | 280 x 130 | 280 x 130 | 280 x 130 |

| Filling height [ cm ] | 140 | 140 | 140 | 140 |

| Filling width [ cm ] | 270 | 270 | 270 | 270 |

| Empty weight [ kg ] | 1,990 | 1,990 | 1,990 | 1,990 |

| Tractor attachment | Three-point category III/IV | Three-point category III/IV | Three-point category III/IV | Three-point category III/IV |

| Drive | H drive: Hydraulic demand 65 l/min. | H drive: Hydraulic demand 65 l/min. | H drive: Hydraulic demand 65 l/min. | H drive: Hydraulic demand 65 l/min. |

| Metering | ||||

| Slide actuation/quantity regulation | Quantity regulation via metering rollers | Quantity regulation via metering rollers | Quantity regulation via metering rollers | Quantity regulation via metering rollers |

| W remaining quantity scales | Yes | Yes | Yes | Yes |

| Electronics | ISOBUS electronics with job computer | ISOBUS electronics with job computer | ISOBUS electronics with job computer | ISOBUS electronics with job computer |

| Section control | 4-fold partial width controller | 4-fold partial width controller | 4-fold partial width controller | 4-fold partial width controller |

| Limited border spreading | Limited border spreading with fixed working width | Limited border spreading with fixed working width | Limited border spreading with fixed working width | Limited border spreading with fixed working width |

![[Translate to English:] AERO 32.1](/fileadmin/duengerstreuer/aero/AERO_rauch_Duengerstreuer_8793_h.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/3/csm_AERO_rauch_mutlirate4_9012_8531f0769f.jpg)

![[Translate to English:] Fine metering shafts](/fileadmin/_processed_/d/5/csm_feindosierwalze-rauch-duengerstreuer-pneumatikstreuer-87-w_2944e224d5.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/d/5/csm_feindosierwalze-rauch-duengerstreuer-pneumatikstreuer-87-w_97aa87fbad.jpg)